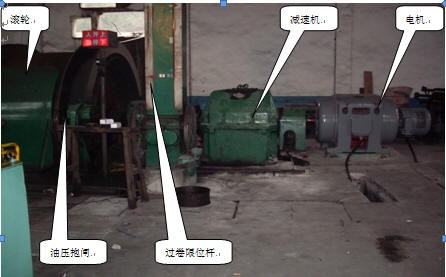

V&T Inverter For Winch Mine Shaft Hoist Solution

一、Introduction

In view of the shortcomings of most of the domestic mine shaft hoist, AC winding motor rotor string resistor for speed control. It has high failure rate, large maintenance workload, poor control performance and serious power waste, the use of frequency drive speed regulation will become a trend.

二、Features of traditional mine shaft hoist

Conventional mine shaft hoist generally use a series circuit of rotor loop resistors, which use the opening and closing of the contactor to achieve step-by-step speed regulation of the motor. This control method has the following obvious disadvantages:

1. The series resistance speed regulation belongs to the pole speed regulation, the starting impact was large. There was a speed jump in the speed switching, which was easy to drop, also high danger. It seriously affects the production efficiency and the safety of people's lives and property, especially when transporting.

2, the use of string resistance speed regulation was a serious waste of electrical energy on the resistance, the lower the speed, the more wasteful; when the object was placed, the motor was in the power generation state, which was a waste of energy.

3. Due to the use of contactor with string resistance for speed regulation, the frequent switching during speed control process makes the contactor damaged frequently, resulting in failure of the speed regulation, which has potential safety hazards and increases the maintenance workload.

4. The stability was poor and the speed changes with the load.

5, the starting torque was not enough, especially It can not be restarted in the slope. Put materials to a stable place to restart, seriously affecting the production efficiency.

三、V&T Inverter for mine shaft hoist control Integration solution.

It has obvious advantages in driving the motor:

1. Adopt advanced DSP chip and excellent vector control to match the power required by the hoist with the output power of the inverter;

2. the starting current was small, the starting speed was stable without impact, greatly reducing the phenomenon of drop;

3. high reliability, the inverter has perfect protection functions, such as over-current and over-voltage overload and short circuit protection functions;

4. Low maintenance workload. There was no need to replace the contactor frequently as in the conventional solution, which greatly reduces maintenance costs;

5. a wide range of speed adjustment. It belongs to stepless speed regulation. The motor control was stable during acceleration and deceleration. The operation was smooth at speed regulation, which improves the reliability of the system. At the same time, there was no heat of string resistance, which greatly improves the working environment of the operator;

6. energy saving space. When mine shaft hoist was in the elevated state, the energy saved was proportional to the speed; when in the lower state, the motor was in the power generation state. If the energy feedback unit was used, the energy saved was not only proportional to the rotational speed, but also the energy fed back;

7. With the automatic switching function of transporting people and cargo, the transporter can automatically limit the maximum speed, making the transporter safer and more comfortable;

8. It can be used perfectly with mechanical brakes and safety circuits. When using mechanical brakes, the inverter will not experience overload and over-current. It can automatically realize mechanical braking in the event of emergency or power failure to guarantee safety;

9. The production efficiency was greatly improved, the stability was high, and the speed does not change with the change of the load;

10. Eliminate the hook phenomenon, even if the mechanical brakes are carried out in the middle of the ascent, do not need to put the heavy objects on the ground to restart, Directly pull the heavy objects without slipping in the middle;

11. The rising and falling processes are interlocked, and it was not easy to have operational errors;

12. When the speed was high, it was not possible to change the running direction casually, to prevent the inverter from automatically stopping or reversing due to the accidental hitting of the signal light during the running;

13. Do not change the original operating habits;

14. Support the switching function of power frequency and frequency conversion;

15.The operation panel has a parameter copy function, which greatly reduces the workload of commissioning and maintenance;

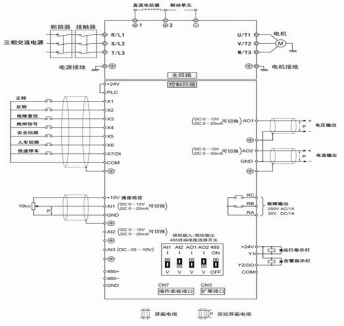

The wiring diagram was as follows (AI2 wiring diagram was omitted)

四、Usage Feedback

V&T frequency drive performs winch control, stable long-term operation, obvious energy saving, unchanged operation and simple maintenance, which can greatly save the user's cost and improve the user's benefit, and won the praise of users everywhere!

Shenzhen V&T Technologies Co.,Ltd. electric drive products voltage class mainly contains 200V, 400V, 690V, 1140V, and the power class varies from 0.4kW to 3000kW, which could meet various application demands from high, medium and low level market. So far V&T products have been exported to over 60 countries like Korea, Germany, England, Russia, UAE, Pakistan, Thailand, India, Australia, South Africa, Mexico etc.