In precision assembly and heavy lifting operations, traditional 50/60 Hz electric hoists often suffer from harsh startup shocks, noticeable swinging, poor synchronization, and rapid brake wear. A manufacturing company addressed these issues by upgrading their hoists with variable frequency drives (VFDs), significantly improving performance and reliability. · The VFD allows smooth control of motor acceleration and deceleration. This eliminates the sudden jolt at startup and the abrupt stop during braking. As a result, mechanical shock drops by about 70%, which greatly extends the life of chains and structural parts. · Because the VFD adjusts power output based on load, multiple hoist points can move in sync. After the upgrade, the height difference between two lifting points stays within ±3 mm. The load remains level automatically after positioning, boosting work efficiency by roughly 25%. · Braking also becomes far more dependable. The system holds the load steady at zero speed before engaging the mechanical brake. This cuts brake pad wear by over 90%. Even if power fails, the motor maintains holding torque to prevent the hook from slipping—making the whole operation safer. Overall, variable frequency technology transforms a basic electric hoist from a simple lifting tool into a precise motion system. It directly tackles three key problems: mechanical shock, inaccurate positioning, and over-reliance on mechanical brakes. For demanding lifting tasks, this upgrade offers a reliable and cost-effective solution.

In the field of industrial automation, variable frequency drives (VFDs), as core equipment for motor control, directly impact the efficiency and stability of production lines. Leveraging its profound technical expertise, V&T has launched the VTS31 series general-purpose VFD—a compact drive offering exceptional compatibility and a rich set of features, delivering an innovative solution for variable-torque load applications such as fans and pumps. The VTS31 series is a compact general-purpose variable frequency drive developed by V&T. It supports both synchronous and asynchronous motor control and comes standard with an LCD keypad. Featuring simple operation, small size, light weight, and comprehensive protection functions, it is ideally suited for variable-torque load applications like fans and pumps. The series covers motor power ratings from 1.5 kW to 500 kW. Key Features: Compact design Supports V/F control, asynchronous current-vector control, asynchronous voltage-vector control, and open-loop synchronous motor control Optimized for fan and pump applications Standard communication protocols: Modbus RTU and CANopen Multiple keypad options: standard Chinese/English LCD keypad; optional LED keypad For models rated up to 650 A: multiple drives can share a common DC bus Cabinet-type units (725 A and above) can be customized to meet specific customer requirements and on-site installation needs regarding input/output wiring configurations

Industry Challenges In traditional constant tension control systems for aluminum strip slitting machines, the unwinding motor operates as a generator. This produces a large amount of regenerative energy. Conventional solutions typically use external braking resistors to dissipate this electrical energy. This approach leads to energy waste, higher costs, and reduced system stability. Innovative Solution V&T offers an optimized control solution based on its specialized tension control inverters, the V6-T-T8 series. This solution features an innovative common DC bus design. Winding Section: Two V6-T-T8 inverters are used. Unwinding Section: One V6-T-T8 inverter is used. Traction Section: One general-purpose V5-H series inverter is used. Key Advantages High Energy Efficiency: During unwinding, the motors generate regenerative power. This power is directly used by the winding and traction motors through the common DC bus. This internal energy recycling greatly improves overall energy savings. Precise Control: The system uses advanced torque control technology. It ensures stable tension, resulting in neater strip edges and higher product quality. Cost Reduction: The system eliminates the need for braking units and resistors. This lowers both the initial investment and ongoing maintenance costs. Stable Operation: The system structure is simplified, and voltage fluctuations are minimized. This ensures continuous, high-efficiency production. User-Friendly Operation: Key parameters can be set with one click. Different process modes, like single or double-side winding, can be switched quickly. The interface is intuitive and displays real-time operational data clearly. Application Results This solution successfully tackles the key challenges of high energy consumption and insufficient control precision in aluminum strip slitting. It achieves effective energy recycling, lowers operating costs, and increases productivity. V&T provides customers with a cost-effective, intelligent, and sustainable drive solution.

The V&T asynchronous servo system has successfully enabled Bock (Dongguan) to complete an energy-saving retrofit of its die casting machines. Following project submission, Germany-based BOCK Group conducted a rigorous nine-month validation process before proceeding with a comprehensive retrofit of its 800T–1000T die casting machines. After an on-site inspection, German engineers were highly impressed by the energy-saving performance and even made a special visit to V&T’s booth at an industry exhibition to commend the technology. In the table, the first row shows pre-retrofit data: 0.7058 kWh per mold.The second row shows post-retrofit data in energy-saving mode: 0.2511 kWh per mold, saving 0.4547 kWh per mold. Based on 1,000 molds per day, 330 operating days per year, and an average electricity rate of CNY 0.8/kWh, the energy-saving benefits are calculated as follows: After more than two years of real-world operation, the system has demonstrated significant advantages: Compact design – easy to install and maintain Simple operation – no specialized training or secondary commissioning required Outstanding energy savings – delivering a comprehensive electricity reduction of 45% to 60%

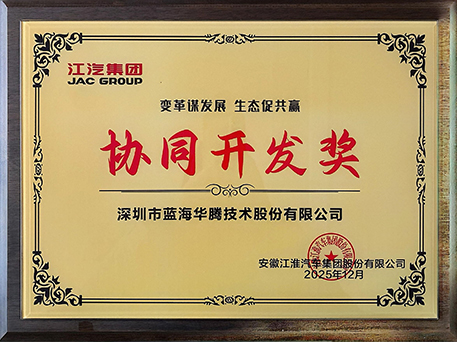

On December 19, 2025, the JAC GROUP 2026 Supply Chain Partner Conference, themed “Driving Transformation for Development, Fostering Ecosystem for Mutual Success,” was held in Hefei. As an important supply chain partner, V&T was invited to attend and received the “Collaborative Development Award.” V&T has rich experience and mature solutions in new energy vehicle technologies, covering pure electric, hybrid and hydrogen fuel cell systems. Over the past few years, V&T has maintained a strong cooperative relationship with JAC GROUP, and its R&D team has actively supported JAC’s development, testing and experiments. This award is a high recognition of V&T’s design and R&D capabilities.

In today’s rapidly evolving and fiercely competitive steel industry, production efficiency and product quality remain the core elements of enterprise competitiveness. Today, we are excited to share a successful case study showcasing how V&T’s V9-H series inverters transformed a 1250 cold roll forming line in a steel mill—demonstrating how this upgrade enabled the production line to achieve a remarkable transformation and embark on a new journey toward high-efficiency manufacturing. The 1250 cold roll forming line is an automated production system designed for processing steel coils with a maximum width of 1250 mm. Functioning like a precision steel-shaping factory, it continuously forms hot-rolled or cold-rolled steel strips into various profiled sections through a cold roll forming process at ambient temperature. The line integrates multiple coordinated units—including uncoiling and feeding, leveling and shearing, cold forming, cut-to-length, and control systems. Its core principle relies on progressive plastic deformation via multiple roll stands to gradually bend the 1250 mm-wide steel strip into the desired cross-sectional profile. Throughout this process, an automated control system ensures precise speed synchronization among all units, accurate dimensional control, and real-time quality monitoring—guaranteeing consistently high-quality output. Urgent Need for Retrofit: The “Growing Pains” of an Aging Line However, as market demands evolve and production pace accelerates, the legacy 1250 cold roll forming line began revealing significant limitations. Mechanical components of the roll stands had aged due to prolonged use, the original inverters were undersized in power rating, and the system operated in open-loop mode using only Modbus RTU (RS485) communication for speed control. These issues led to sluggish mechanical response and poor speed synchronization across the multiple drive shafts of the roll stands. Operators were forced to constantly and manually fine-tune speed ratios between drive axes just to maintain minimal synchronization. This not only imposed heavy labor demands but also severely compromised production speed, output capacity, and product quality—making a comprehensive upgrade imperative. V&T V9-H Series Inverters: The “Key” to Transformation To better adapt to changing market conditions and enhance the overall capability of the cold roll forming line, a targeted retrofit of the roll stand drive system was launched—with V&T’s V9-H series inverters playing a pivotal role. On the mechanical side, motors, gearboxes, and drive shafts of the roll stands underwent thorough inspection and precise realignment. Encoders were added to the motors to enable closed-loop control, significantly improving motor responsiveness and laying a solid mechanical foundation for higher-speed operation. On the electrical side, modern intelligent control components—including an HMI touchscreen, PLC, and V&T V9-H inverters—were integra...

Season's Greetings from V&T Merry Christmas and Happy New Year! As the holidays approach, we'd like to thank you sincerely for your support and trust this year. We're full of anticipation for future cooperation, and look forward to deepening our partnership to create more success together in the new year. Thank you for your unwavering trust and companionship. Wishing you a festive holiday season filled with joy.

Three approaches have been adopted for the variable frequency speed control retrofit of sucker rod pumps 1.Variable Frequency Drive (VFD) with Braking Unit Control By adding a braking resistor and a braking unit to both ends of the DC bus in the main circuit of the VFD (this method has a high cost-effectiveness ratio), due to the need for high torque during the startup and ascending phase of the sucker rod pump, and during the descending phase, the motor is in a power generation state. The most critical part is the descending phase, which is a continuous operation process, while adjusting the reciprocating motion per minute according to the oil viscosity, well depth, and production rate, causing the motor to enter a regenerative power generation state, feeding excess energy back to the grid, leading to an increase in the voltage on the DC bus of the main circuit of the VFD. Without a path for electrical energy to flow back to the grid, it must be dissipated locally using resistors. This is why we must use a braking unit and braking resistor on the VFD, and our company's high-power VFDs can have built-in braking units, fully achieving the desired control effect. 2.VFD with Regenerative Feedback Unit Control A regenerative feedback unit is added to the DC circuit of the VFD to feed the electrical energy generated during the motor’s regenerative (power generation) state back into the grid. 3.VFD Automatic Intelligent Control — No Braking Unit or Regenerative Feedback Unit Required In general, no braking unit or regenerative feedback unit is required. The VFD can automatically adjust its operation according to the working conditions of the beam pumping unit, resulting in lower system cost, higher reliability, reduced harmonic pollution, and better adaptability to operating voltage variations. Two-Location Control for the Variable Frequency Speed Control System As per requirements, each variable frequency speed control cabinet is equipped with one VFD, which automatically controls the motor in open-loop speed mode. The control cabinet features a switch between line-frequency (bypass) and variable-frequency operation, offering three positions: line-frequency, variable-frequency, and stop—ensuring simple and convenient operation. When switched to variable-frequency mode, the VFD runs automatically. Speed adjustment is achieved by feeding an analog signal from the potentiometer on the control cabinet to the AI1 terminal of the VFD. During operation, real-time parameters such as current, voltage, power, and frequency can be viewed directly on the VFD’s display panel. For upper-level (remote) control, no switching is required—the VFD can be started and stopped directly, and its operating status and running frequency can be set remotely. Current operational data can also be copied and exported into documentation. Product Advantages: Comprehensive protection against external faults, including short circuit, phase loss, overload, and phase imbalance; Hi...

On November 28, 2025, V&T officially launched its initiative to establish a management system aligned with the ISO/SAE 21434 standard, "Road Vehicles – Cybersecurity Engineering." This move is not a sudden leap of disruptive innovation within the industry, but rather stems from long-term observation and careful assessment of automotive intelligence trends. The goal is to enhance cybersecurity resilience throughout the entire product lifecycle through a systematic framework, thereby providing more reliable foundational support for product safety in the era of intelligent connected vehicles. As 5G, AI, and IoT technologies continue to converge, automobiles are evolving from traditional means of transportation into mobile intelligent terminals. While innovations such as in-vehicle infotainment systems and advanced driver-assistance functions significantly improve user experience, they also introduce potential risks—including data breaches and unauthorized remote control. Industry statistics indicate a marked increase in global automotive cybersecurity incidents in recent years, with hackers employing increasingly sophisticated attack methods that legacy functional safety standards can no longer adequately address. Against this backdrop, ISO/SAE 21434—the world’s first international standard for automotive cybersecurity—offers critical value by embedding cybersecurity management into every phase of a vehicle’s lifecycle: design, development, production, operation, maintenance, and end-of-life disposal. Leveraging Threat Analysis and Risk Assessment (TARA) methodologies, the standard enables organizations to identify attack surfaces, quantify risk levels, and implement targeted mitigation strategies. For instance, regarding communication interfaces between in-vehicle systems and external devices, the standard mandates encrypted communications and access control mechanisms to prevent data theft or tampering. In an industry landscape often fixated on “technological breakthroughs,” V&T’s approach stands out for its restraint. Company leadership stated, “There is no such thing as ‘absolute security’ in cybersecurity, but we can continuously reduce the probability of incidents through iterative improvements. We prefer to be long-term thinkers, making steady investments to create replicable, practical examples for the industry.” This philosophy aligns closely with broader industry trends. Under United Nations Regulation No. 155 (UN R155), starting in 2024, all vehicles and components exported to Europe must obtain certification under a Cybersecurity Management System (CSMS)—with ISO/SAE 21434 serving as its core supporting standard. V&T’s systematic implementation thus responds proactively to international compliance requirements while demonstrating its commitment to advancing high-quality development in China’s intelligent connected vehicle sector. In the race toward intelligent mobility, cybersecurity has become an invisible yet existential th...

The EX-MT09 is a dedicated flying shear controller designed for corrugated board cross-cutting applications. When paired with the V&T V6-H high-performance vector drive, it enables precise flying shear control. The EX-MT09 utilizes a high-performance DSP chip from Texas Instruments (TI), offering fast computation speed, built-in flying shear control algorithms, high-speed communication capabilities, high cutting accuracy, strong expandability, and convenient system upgrades. System Control Architecture HMI Interface + EX-MT09 Controller + V6-H Drive + AC Servo Motor Product Overview The EX-MT09 flying shear controller features a high-performance core DSP chip that ensures rapid computation. It offers simple interfaces, excellent compatibility, and ease of maintenance, meeting stringent requirements for high-precision (cutting error < ±1 mm), high-speed, wide-web, efficient, and highly reliable corrugated board cutting. The controller receives position signals from the pull motor, calculates in real time, compares them with feedback signals from the cutter motor, executes its built-in flying shear algorithm, and drives the servo motor to precisely track the target position—ensuring overall electrical system control accuracy. System Control Diagram Advantages of the EX-MT09 Flying Shear Controller Solution Rich hardware resources, high expandability, and easy system upgrades; Built-in flying shear algorithm with modular interface design for simplified commissioning; High cutting precision, wide web handling capability, and high operating speed; Smooth start/stop operation with minimal mechanical shock, fast and accurate positioning, rapid speed response, and excellent high-speed synchronization performance; Fully automatic job changeover without waste paper generation, featuring dynamic length compensation during acceleration/deceleration cutting; Open system architecture enabling seamless integration and interoperability with equipment from other manufacturers—especially production management systems.

The VA-MQ cross-cutting servo drive is a high-performance servo drive developed on V&T's advanced vector control and torque control core drive platform, integrating both cross-cutting flying shear control algorithms and motor servo drive control algorithms. 1、System Control Solution HMI Interface + VA-MQ (with built-in flying shear control algorithm) + AC Servo Motor 2、Product Overview The VA-MQ servo drive features rapid speed response, high output torque, and advanced vector control, torque control, and servo control technologies aligned with international leading standards. It meets the demanding requirements of corrugated board cutting applications—high precision (cutting error less than±1 mm), high speed, wide material width range, high efficiency, and high reliability. The drive integrates a specialized cross-cutting flying shear control algorithm and servo motor drive algorithm, enabling precise positioning and fast-response synchronous speed tracking. 3、System Control Diagram 4、Advantages of the VA-MQ Control Solution Dual-core DSP control – Delivers superior control performance. Built-in flying shear algorithm – Simplifies wiring and enables easy commissioning. High-precision, wide-width, high-speed cutting – Meets demanding production requirements. Smooth start/stop with minimal mechanical shock, fast and accurate positioning, rapid speed response, and excellent high-speed synchronous tracking. Supports external capacitor box – Enhances energy efficiency and ensures stable, reliable operation. Fully automatic job changeover without waste paper, featuring dynamic length compensation during acceleration/deceleration for consistent cut accuracy. Open system architecture – Easily integrates and interfaces with equipment from other manufacturers, especially production management systems.

In today's era of rapid industrial automation, drives serve as critical components ensuring the stable operation of numerous mechanical systems. Their performance directly impacts the efficiency and quality of production processes. Leveraging deep technical expertise and continuous innovation, V&T has meticulously developed the DTS800 series of multi-drive inverters. With distinctive technological advantages, a comprehensive product portfolio, and broad applicability, the DTS800 series delivers reliable and high-performance power solutions across a wide range of industrial sectors, significantly contributing to industry advancement. The DTS800 series is V&T’s self-developed multi-drive inverter platform, featuring proprietary Direct Torque Control (DTC) technology. It offers fast torque response and superior speed regulation accuracy, supporting both encoder-based and encoderless DTC operation. Thanks to its unique DTC algorithm, the drive maintains high low-frequency torque and rapid torque response even without an encoder, satisfying the requirements of most industrial applications. The V&T DTS800 drive family includes: DTS800-H series: Single/multi-drive inverter units DTS800-D series: Basic rectifier units DTS800-S series: Parallel slave inverter units DTS800-R series: IGBT rectifier/regenerative units DTS800-MCB: Parallel master control unit The DTS800 series supports both single-drive and multi-drive configurations. It also enables multiple inverter units to operate in parallel to drive a single motor, facilitating scalable power capacity through parallel operation. Available in two voltage classes—three-phase AC 380V and AC 690V—the series covers a wide power range from 75 kW to 2,240 kW. Product Features: Control Algorithm Employs advanced Direct Torque Control (DTC) technology, optimized for asynchronous motors. Enhanced motor control robustness. Reduced sensitivity to motor parameter variations. Fast torque response capability. Supports both scalar (V/f) control and Direct Torque Control (DTC). Usability Standard equipped with an LCD operation panel. Menu-based parameter structure with a dedicated setup menu for initial commissioning. Parameter options designed for intuitive selection. Five default display screens, switchable at will; users can freely customize the information shown on the default display. Supports parameter upload and download. Enables PC-based commissioning and waveform capture via host software. Built-in web server allows browser-based debugging—no PC software installation required. Supports remote firmware upgrades. Mechanical Design Book-style drive unit design for compact and modular installation. Full series powered by DC bus with integrated pre-charge (buffer) circuit. Recessed terminal layout for control wiring, enhancing protection and ease of access. Communication Supports Modbus-RTU, CAN, PROFINET, and PROFIBUS-DP communication protocols. Encoder & Pulse I/O Compatible with optical encoders. ...

The controller is the core component of an electric bike, acting as its "brain." It controls the motor’s start, stop, direction, speed, and other electronic parts. How it works: The controller actively manages the motor, making it run in the desired direction, at the right speed, and with smooth response. In electric vehicles, it uses power from the battery and converts it to run the motor. It responds to user inputs like throttle, brake, and gear selection. This controls how the vehicle moves—whether it’s starting, speeding up, climbing a slope, or braking. It can also help with braking energy recovery, storing some of that energy back into the battery. V&T now introduces a new series of electric vehicle controllers. We provide core power solutions for electric vehicle manufacturers. This series is built to be reliable, high-performing, and easy to adapt. It’s designed to be the ideal power control partner for your product line. Wide Compatibility This controller series is designed for popular types of electric vehicles, including: Electric mopeds Electric motorcycles Electric forklifts Electric golf carts The power range covers 250W–450W, 350W–1500W, and 1500W–3500W. We offer solutions for both hub motors and mid-drive motors. The design is flexible, so it can meet different power needs across your product range. Built to High Safety Standards We follow strict industrial standards to make sure our controllers are safe and reliable over time: High voltage resistance: AC1500V rating, for better reliability during voltage surges. Strong water resistance: IPX7 waterproof rating, so it works well even in harsh conditions. Flame-retardant materials: Key parts use V0-grade materials for improved safety. Key Benefits for Better Performance Easy to install and maintain: Plug-in terminals make assembly simple and reduce maintenance time. Good heat control and stability: We use a cast aluminum heat sink and a layered circuit board design. This helps heat spread evenly and keeps the controller stable during heavy use. Works in tough conditions: The shell is waterproof and protected against interference, high voltage, and short circuits. This means it can handle different environments well. Smooth power control: It accurately controls motor current, which helps the vehicle run smoothly and respond well. Better riding experience: Special motor control algorithms keep the ride steady, especially at high speeds, for a more comfortable feel.

Amid the urban hustle, certain landmarks instantly define a city's character. The Shenzhen Bay MixC Music Fountain is one such landmark. Chosen for V&T's proven expertise and reliable partnership, VFDs serve as the core component driving this spectacular water feature. V&T variable frequency drives are instrumental in transforming a basic hydraulic setup into a dynamic, energy-efficient art installation. Their advanced drive and control capabilities elevate the entire performance. Precision Control The fountain's 13 independent water channels are individually controlled by VFDs, enabling seamless speed adjustment. This allows for diverse water formations—from majestic "curtain" falls to gentle "stream" flows—creating a visually layered experience. Energy Efficiency The system eliminates the need for constant full-load operation. Like an intelligent conductor, it adjusts power output based on the scenario—daily operation, holiday shows, or night displays—significantly reducing energy use and operational costs. Smooth Operation & Durability Soft start and stop functions prevent mechanical shock and water hammer effect, minimizing wear on pumps and pipes. This extends the system's lifespan and reduces maintenance needs. Adaptive Intelligence Programmable settings allow effortless switching between operational modes—from a powerful daytime display to a dreamlike nighttime scene. The system can even mimic natural water movements. Its robust design ensures that if one drive fails, the others continue operating normally. In this fusion of art and technology, V&T VFDs prove to be more than components—they are the soul of the "Water Symphony." Moving forward, V&T remains committed to breathing life into urban landscapes through innovation.

At the recently opened 134th Canton Fair, Shenzhen V&T Technologies Co., Ltd. became one of the notable highlights with its strong product lineup and innovative technologies. The company made a grand appearance, showcasing core products such as VFDs, electric vehicle motor controllers, hybrid solar inverters, and servo systems, attracting a large number of domestic and international business visitors for discussions and exchanges. V&T's series of VFDs, with their exceptional energy-saving effects and stable control performance, became a focal point for customers in the field of industrial automation. Utilizing advanced control algorithms, these products enable precise motor speed regulation and have demonstrated outstanding performance across various industrial application scenarios. The servo products exhibited by the company, known for their high response and high precision, meet the demands of complex industrial applications. Live demonstrations drew significant interest from numerous professional visitors. In line with the global energy transition trend, V&T Technologies introduced its new energy vehicle motor controller, which features innovative design that effectively enhances the energy efficiency and driving range of electric vehicles, making it a standout highlight at the event. The hybrid solar inverters, as one of the company's key showcased products, received high recognition from business visitors in regions such as the Middle East and Europe, thanks to their high conversion efficiency and reliable performance. The V&T Technologies booth was bustling with visitors, including a continuous stream of procurement delegations from Belt and Road Initiative countries and RCEP member nations. Technical staff patiently and meticulously explained product features and demonstrated performance to every visiting business representative. "We are very interested in V&T Technologies' photovoltaic inverters," said a procurement delegate from the Middle East. "The product's performance and stability fully meet our requirements, and we have preliminarily reached a cooperation intent." During the fair, the V&T Technologies booth received visitors from over 50 countries and regions worldwide, secured multiple intent orders on-site, and established initial cooperative relationships with more than ten overseas clients.

The 25th China International Industry Expo concluded successfully. As a dedicated player in industrial automation and new energy, V&T engaged in in-depth exchanges with numerous industry partners and professional visitors during the five-day event, showcasing its full range of products, dynamic technology demonstrations, and systematic solutions. Together, they explored practical directions for smart manufacturing in the new energy and industrial automation sectors. Full Product Portfolio: Addressing Needs with Solid Technical Capabilities At this year’s expo, V&T highlighted its comprehensive product line for industrial automation and new energy, including frequency converters, servo drives, electric vehicle motor controllers, elevator drive and control systems, and photovoltaic energy storage systems. Among the spotlighted products were the V6-H Series electric vehicle motor controller, V9 Series frequency converter, VTS30 Series frequency converter, VTS300/400 Series frequency converter/servo drive, DTS800 Series multi-drive system, V9-HCF high-carrier frequency liquid-cooled frequency converter, V9-BA pass-through heat dissipation frequency converter with anti-cotton and anti-metal dust features, V9 high-protection IP67 frequency converter, VA Series spindle servo drive, and VTF energy feedback unit. These products attracted significant attention for their reliable performance and adaptability. In the dynamic demonstration area of the booth, V&T's eight-axis servo motor control system showcased multi-axis synchronization effects through complex trajectory movements, powered by the coordinated operation of the VS510 Series EtherCAT bus servos, DP2000 touchscreen, and VC3 eight-axis motion controller. The demonstration vividly highlighted the system's performance in control precision and flexibility. This presentation captured the attention of clients from industries such as machine tools, textiles, and laser equipment. Several corporate representatives remarked after the experience, "The eight-axis servo motor control system demonstrates the coordination effects very clearly. It can address the control challenges we face in our equipment operations, and we look forward to further discussions on potential applications." Systematic Solutions: Providing Practical Support from Equipment to Scenarios At this exhibition, V&T showcased its integrated five-tier solution encompassing the "Industrial IoT Platform, Edge Layer, Control Layer, Drive Layer, and Execution Layer." This architecture enables equipment interconnection and intelligent decision-making through seamless data integration, delivering actionable support for various industries such as textiles, air compressors, elevators, energy conservation, and intelligent water supply. Leveraging an industry-specific algorithm library and flexible configuration tools, the solution can be rapidly tailored to meet the customized needs of different scenarios. During the event, several co...

Dear Valued Customers, Please be advised that our company will be closed from October 1st to October 8th, 2025 in observance of two important Chinese festivals: National Day: Celebrating the founding of the People's Republic of China. Mid-Autumn Festiva: A symbolic occasion for family reunions, marked by sharing mooncakes and admiring the full moon. Our office will resume normal operations on October 9th, 2025. Please note that order processing and email replies may experience delays during this period. We apologize for any inconvenience this may cause. We truly appreciate your continued support and cooperation. We look forward to serving you again after the holiday.

The mine hoist plays a central role in coal mining. It moves coal and waste rock from underground workings to the surface. It also carries workers, supplies, and equipment up and down the mine. Older hoists use wound-rotor motors with resistor-based speed control. This method wastes a lot of energy. Nearly one-third of the electricity is lost as heat in the resistors. Speed regulation is uneven and inefficient. At lower speeds, the motor performs poorly. It becomes weak and unsteady. The equipment suffers from heavy shocks. This leads to breakdowns and accidents. It also requires constant upkeep. Parts like contactors and brushes wear out quickly. The mechanical brake system takes a lot of abuse. Maintenance is expensive and time-consuming. Application of VFDs in Mine Hoist Using a V&T VFD changes everything. It provides strong torque even at very low speeds. The hoist starts and stops smoothly. There’s no creeping or sudden jerks. Everything runs more steadily. The speed adjusts smoothly without steps. There’s less shock to the gearbox and brake. That means less wear and longer life for the equipment. There’s no need for old-style contactors or brushes. Simple squirrel-cage motors work perfectly. Maintenance becomes much easier. The drive also includes full protection and monitoring. Used together with a PLC, it makes the whole system far more reliable. And best of all—it saves energy. No more wasting power on resistance banks. With the V&T drive, mine hoists run safer, smoother, and more efficiently. They also cost less to maintain. It’s a modern solution that helps keep mining operations running continuously.

In industrial production, the efficient and stable operation of speed control systems is paramount. Traditional systems often face challenges like low power factor, difficulty in energy regeneration, and significant harmonic interference, constraining production efficiency and quality. Active Front End (AFE) technology provides an effective solution to these issues. V&T's DTS800 Series AFE products are designed precisely to meet the demands of high-performance speed control. An AFE is a drive unit that supplies DC power to a variable frequency drive (VFD) via PWM rectification while simultaneously regenerating braking energy from the motor back to the grid. Together with the motor drive section, it forms a complete AFE speed control system, enabling four-quadrant operation for motor-driven speed regulation. DTS800 Series Core Components: DTS800-R AFE Rectifier/Regeneration Module: Supports constant voltage, constant current, and constant power modes. Performs sinusoidal PWM rectification and energy regeneration. Ensures the resulting AFE system delivers low grid-side current harmonics. DTS800-H Drive Inverter Module: Employs independently developed DTC (Direct Torque Control) technology. Delivers rapid torque response and high speed regulation accuracy. Supports DTC control with or without an encoder. Unique DTC technology ensures excellent low-speed torque and fast torque response even during encoderless operation Wide Application Scope: The DTS800 Series AFE products are ideally suited for applications requiring stable power supply and efficient regeneration of motor braking energy to the grid, including: Crane equipment, centrifugal equipment, oilfield equipment, experimental test platform, opposite drive system, downhill conveyor belt, winch. The V&T DTS800 Series AFE products demonstrate solid and reliable characteristics across key aspects: four-quadrant operation capability, energy regeneration efficiency, control algorithm implementation, ease of use, communication support, and structural design. Their robust and high-performance nature precisely meets the stringent requirements of modern industrial production for speed control systems while aligning with industry trends.

In factories, inverters are key for controlling motors, helping them run at the right speed and save energy. Sometimes, several motors need to run at exactly the same speed, or work together to move one big thing, like a long production line. Using one bigger inverter to control multiple motors at once can be a cheaper and smarter way to do this. How you start the motors decides which method you use: starting them all together, or starting them one after another. Method 1: Starting and Stopping Together When to Use It: When motors (especially identical ones, made by the same factory) must run at the same speed, perfectly in sync. How It Works: One large inverter powers all the motors simultaneously. They start and stop together. The Big Plus: It saves money and gets the job done well. Picking the Right Inverter: The inverter must be big enough to handle all motors combined. The inverter must be strong enough (provide enough electrical current) for all the motors. Its rated current needs to be at least 1.2 times the total current all the motors use. Important Things to Remember: Control Mode: You must use open-loop V/F control. Other smarter controls need details about one specific motor and won't work well here. Matching Motors: The motors shouldn't be too different in size. It's best if they are the same model, made by the same company, even the same batch. This helps them run together smoothly. Watch the Wires: Keep all the wires running from the inverter to the motors as short as possible. Long wires cause problems. If the total wire length is too long, you might need extra parts (like an output reactor or filter) near the inverter. Protect Each Motor: Every single motor needs its own thermal overload protector (like a heat-sensing switch) right before it. This protects it if it gets too hot. Stopping Fast: If the motors need to stop very quickly, you'll likely need a special braking unit and resistor. Some smaller inverters have the braking unit built in—just add the resistor. Method 2: Starting One After Another When to Use It: When different parts of a machine need to start at different times. How It Works: The inverter acts like a power source. You switch its power to one motor at a time. The Big Plus: You need fewer inverters, saving cost. The Critical Rule: Never, ever let two or more motors run from the inverter at the same time. If this happens, the inverter will be overloaded and likely damaged. In Summary Using one inverter for multiple motors (starting together or separately) is a smart, money-saving trick in factories. To make it work safely and well, you must pick an inverter that's powerful enough and follow the specific rules for how you start the motors (like using the right control mode, matching the motors, keeping wires short, adding individual motor protection, and preventing overlap). Doing this right means reliable equipment and lower costs.

V&T, working with Zhongchuang Minghui, has successfully installed its new grab crane control system at Dongdaqiao Station and Future Science City Station. Customers report good results. Solving Old Problems: The older way to run these cranes used cam controllers, contactors, and resistors. This method caused several issues: machines broke down often, wiring was complicated, they wasted power, and operators couldn't adjust speeds very well. How V&T's Frequency Converters Help: Smarter Grab Control: The operator sends a signal. The control system (PLC) then checks the motors' current, torque, and speed. V&T frequency converters adjust the motors' speed and power smoothly. This keeps the grab bucket moving efficiently and stops material from spilling. Even if mistakes happen: If the grab opens too soon while lifting, the operator doesn't panic. Using low speeds 1 or 2 for about ten seconds lets the grab close itself. This makes the job easier and needs less skill. Better Visibility for High Work: When the crane works high up, operators struggle to see the grab bucket clearly. This slows things down. V&T's system shows everything important on a touchscreen. Operators work faster and don't need years of experience. Smooth Speed Changes & Savings: The grab open/close motor uses 3 speed settings. Other motors (trolley, bridge, auxiliary hoist) use 4 settings. V&T frequency converters make all speed changes very smooth. Starting is gentle, low speeds are steady, and less electricity is wasted as heat. This is easier on the motors, especially with lots of stopping and starting, helping them last longer. A shared power setup (DC bus) for the main and travel drives uses fewer cabinets, lowering the customer's costs. Easy Monitoring & Fixes: All V&T frequency converters connect to the PLC using communication cables. The PLC connects to the touchscreen. Operators see the system status and data on the screen. They can also change some settings there easily. If something goes wrong, the screen shows exactly where the problem is, including specific error messages from the frequency converters. This helps technicians fix things fast. The Result: V&T frequency converters provide smooth starting, precise speed control, and strong protection. Combined with the PLC, they create a safer, more accurate, and efficient way to run grab cranes. The clear touchscreen display is key. The success at Dongdaqiao and Future Science City shows V&T's system improves crane automation, efficiency, and ease of use.

Product Overview The V9-HCF high-carrier series inverter is a high-performance vector inverter designed for medium- and high-power high-speed motor applications. Based on the study of inverter drive and hardware/software requirements in high-speed applications, this series is specially developed to better meet the needs of high-speed motor driving. The product comes in air-cooled and water-cooled versions. In terms of structure, users can choose between wide and narrow body types. Product Features 1.Control Algorithms Uses advanced high-speed motor control algorithms Works with both synchronous and asynchronous motors Offers strong high-speed control and deep flux weakening capability Supports multiple control modes: synchronous motor closed-loop/open-loop, asynchronous motor closed-loop, V/F, asynchronous motor current vector, and asynchronous motor voltage vector 2.Structural Design Offers two structural styles: traditional and book-style narrow type Designed with heat dissipation in mind for high-power motor applications Even under the standard 10K carrier frequency, the components show excellent thermal performance The entire series supports shared DC bus operation 3.User-Friendliness Comes with an LCD control panel Parameters are organized in a menu-based structure, with separate menus for initial setup Five default display interfaces can be switched, and default display content can be customized Parameters can be uploaded or downloaded with one button Supports PC-based debugging and waveform capture 4.Communication Standard Modbus-RTU/CAN communication included Optional PROFINET or Profibus-DP communication modules available Power Range Wide-body water-cooled type: 3 AC 380V, 110–630kW Narrow-body water-cooled type: 3 AC 380V, 75–500kW 3 AC 690V and air-cooled models are available upon request Application Scenarios The V9-HCF high-carrier series inverter is widely used in high-speed blowers, magnetic levitation systems, air suspension systems, high-speed air compressors, and municipal wastewater treatment plants — all typical high-power, high-speed motor applications. Field Applications

Product Overview V&T FV81-C series high-voltage soft starters are designed specifically for 6–10 kV AC motors. They use advanced computer control, digital signal processing, and high-power thyristor technology. These soft starters help manage starting current, reduce stress on the power grid and mechanical systems, and ensure safe and stable motor operation. The FV81-C series provides smooth motor startup and shutdown, supports remote monitoring and control, and features a compact design with high reliability. It is an ideal choice for medium- and high-voltage induction motors. Power Range 6 kV: 420–5,000 kW 10 kV: 420–15,000 kW Custom options are available for other voltage levels. Field Applications

Product Introduction V&T FV81-H series high voltage inverters are designed for energy-efficient speed control of high-voltage motors. Built on the company's strong experience in low-voltage inverters, this series uses mature power unit cascade technology. It also integrates advanced vector control algorithms. These features ensure high reliability, ease of operation, and excellent performance. The FV81-H series is widely used in speed control for fans, pumps, compressors, and similar equipment. The FV81-H series comes with an integrated design that simplifies installation and retrofitting. Its comprehensive protection and control functions help maintain stable system operation. With outstanding performance, reliable operation, and strong energy-saving results, this series has gained recognition from many users. It is now widely used in industrial applications. Whether for new projects or upgrades, the FV81-H series offers an ideal solution that adds real value for users. Power Range 6kV: 220–5000kW 10kV: 220–20,000kW Custom solutions are available for other voltage levels upon request. Field Applications

In modern building material factories, block making machines are the main workhorses. They run automatically, make many kinds of blocks or bricks, and produce large quantities. The part that shakes the mix to form the block is the heart of these machines. How well this shaking part works decides how good the machine is and how good the blocks turn out. For a long time, these shakers used motors or hydraulic pumps running at fixed speeds. But now, using a variable frequency drive (VFD) to control the motor speed for the shaker has become the better way. Many machine makers prefer this method. Here's why VFDs make a big difference: Better Control for Better Blocks: VFDs let workers easily change how fast the shaker vibrates and how strong it shakes. The machine can remember the best shaking settings for different block types. Workers can control starting, speeding up, slowing down, and stopping smoothly. This makes blocks much denser and gives them a smoother, nicer finish. Faster Work, More Blocks: The shaking part speeds up and slows down very quickly with a VFD. This makes each block form faster. Because blocks form quicker, the whole machine can make more blocks every hour. Gentler Starts, Less Wear: VFDs let the motor start very gently. This uses less power at startup and doesn't stress the electricity supply. It also means less sudden force hitting the machine parts. This causes less damage over time, meaning fewer breakdowns and cheaper repairs. Saves Power, Runs Cooler: VFDs manage the motor's power more efficiently. Less power gets wasted, saving electricity. The motor also doesn't get as hot, which helps it last longer and work reliably. Stable Power, Fewer Stops: VFDs have built-in voltage control (called AVR). Even if the building's power voltage gets low, the VFD can still give the motor enough steady power to work. This keeps the machine running and prevents unexpected stops. Easy to Use: Systems using VFDs are simple to operate and adjust. They need fewer wires to connect and have special controls that make setting things up easier. Why VFDs Matter: Putting a VFD on the shaker motor isn't just about changing speed. It makes the whole block making machine work better. Blocks come out stronger and look nicer. The machine makes more blocks per hour. It uses less electricity and needs less fixing. Because the machine runs more smoothly and stops less often, it's a smarter choice for factories wanting good, reliable equipment. VFD technology is now key for modern, efficient block making.

Introduction Slitting machines are key equipment in paper and packaging plants. They cut wide rolls of paper or film into many narrow strips. Keeping the material tension steady is very important. It makes sure the cuts are clean and the widths are exact. Old slitting machines often use magnetic particle clutches to control tension. These clutches work well for small tensions at slow speeds. But they cause problems at high speeds. The friction creates a lot of heat. This heat shortens the clutch life and limits how fast the machine can run. Challenges in the Pressroom Running these machines in a busy printing factory is hard. There are several problems: Sudden Load Changes: Starting, stopping, and changing rolls puts big, instant stress on the motor. Many drives can't handle this shock. They stop working. Tough Environment: The air is full of dust. Temperatures get hot. These conditions are hard on electrical parts. Need for Precision Control: Sometimes three motors work together on one machine. They must run at exactly the right speeds. If they don't, the cut material won't be straight or the same width. How V&T Drives Help V&T drives solve these pressroom problems effectively: They Handle Heavy Shocks: V&T drives manage the big load spikes during start, stop, and roll changes. They keep the machine running. Other drives often trip and cause shutdowns. They Work in Tough Conditions: V&T drives are sealed against dust. Their cooling works well, even when it's hot. We know this works. These drives have run reliably in printing factories for 12 years. Dust and heat haven't caused major breakdowns. They Control Speed Precisely: V&T drives control motor speed and power very accurately. When multiple motors need to work together smoothly, these drives make it happen. This keeps the material tension steady. The result? Material is cut cleanly and evenly, every time. The Benefits Using V&T drives on slitters fixes issues with older clutch systems, especially at higher speeds and with sudden loads. They also handle the difficult pressroom environment well. Customers get important advantages: More Machine Uptime: Fewer stops from load shocks or environment problems mean the machine runs longer. Better Quality Cuts: Precise speed and tension control ensure accurate sizes and clean edges. Built for the Job: These drives handle common pressroom dust and heat, lasting longer. Potential for Faster Speeds: They provide the stable power needed to try running slitters faster than older clutches allowed. Conclusion Slitting machines need drives that are tough, reliable, and precise. V&T drives deliver on all three. They handle shocks, work in dusty heat, and control speed accurately. Their real-world performance is proven. For 12 years in actual pressrooms, they've been reliable. V&T drives are a solid choice. They help customers get more from their slitting machines.

Today, clean air and efficient operation matter more than ever. V&T proudly introduces our advanced Oil-Free Scroll Air Compressor. This innovative machine is made for places where air quality is critical. It's the perfect power source for labs, healthc What is an Oil-Free Scroll Air Compressor? This compressor is a big step forward in air technology. Unlike old piston compressors, it doesn't need oil for lubrication. It uses a special scroll movement to squeeze the air. This guarantees the air coming out is completely oil-free. You get cleaner air, less maintenance, and no risk of oil contamination. It gives you peace of mind. How It Works: The Smart Heart of the Machine The orbiting scroll rotates in the order shown in Figure 1-2-3-4. The crescent-shaped compression chamber gradually decreases in volume, compressing the gas inside. The compressed gas is then discharged from the center of the fixed scroll. Two precise spiral scrolls work together: Fixed Scroll: This part stays still. It forms the main compression chamber. Moving Scroll: A motor drives this part. It orbits in a tight circle around the fixed scroll. Air gets pulled in. It gets trapped between these two scrolls. The moving scroll squeezes the air pockets smaller and smaller. Pressure builds steadily. Finally, clean, compressed air pushes out through the center. The scrolls never touch metal-to-metal. So, it needs no oil at all. This stops oil from ever getting into your air. Why Choose Our Oil-Free Scroll Compressor? Perfectly Clean Air: Meets the strict ISO 8573-1 Class 0 standard for oil-free air. This means absolutely no oil, mist, or vapor in your air supply. Gives you zero-risk air for critical jobs: precision labs, sterile drug making, safe food production, and high-end electronics. Super Quiet Operation: The unique scroll design doesn't need parts to touch, so it runs much quieter. It works smoothly and quietly. Fits right into noise-sensitive places like labs, hospital rooms, cleanrooms, or offices. Makes the workspace better. Great Energy Savings: Squeezes air in one smooth, continuous motion. This wastes less energy. Uses less power than old piston compressors. Saves you significant money on electricity bills over time. Good for your budget and the planet. Compact Size, Saves Space: Built in a smart, modular way. It's small and simple. Fits easily under lab benches, in tight equipment corners, or other small spots. Makes the best use of your valuable space. Built to Last, Easy to Care For: The oil-free design means fewer parts can break. It runs reliably for a long time. Maintenance is very simple. Mainly, just change the air filter regularly. Saves you time and money on upkeep.

XCMG Heavy Duty's electric mining dump trucks are now running in mines in Southwest China. These trucks use V&T's special motor controller. The order is worth about 16 million yuan. Mine operators chose these trucks because they handle tough jobs well and meet special needs. This is a big step towards cleaner "green mines". These electric trucks are as strong as XCMG's older fuel-powered ones. They have a tough cargo box, strong frame parts, and a solid body. They carry very heavy loads well. The V&T controller helps the transmission learn by itself. It learns during gear changes and when the truck powers down. This fixes problems caused by wear over time. Shifting gears becomes smooth and exact. The truck works reliably in many situations – flat ground, hills, or water. You don't need to keep resetting its software. Driving is comfortable too, with adjustable seats, strong springs, and a cab designed for a good view. Being electric, these trucks are cleaner, quieter, and save energy. Their special motor braking system captures energy when slowing down. It saves over 10% of the energy this way. The whole system runs very efficiently, over 80% of the time. The V&T controller makes everything work together better – the motor, the gearbox, and the battery. This smart teamwork means the truck uses at least 5% less power than similar trucks. On regular mine routes, it learns from data about how the truck moves. Then it figures out the best times to shift gears and how to use energy, saving even more power. Many electric vehicles struggle with how far they can go and how strong they are. XCMG's electric mining truck handles this well. It uses safe and powerful lithium iron phosphate batteries. These batteries hold nearly 200 kilowatt-hours of power. Clever control helps the truck go further on a charge. It starts with huge force – up to 18,000 Newton-meters of torque. It can go from 0 to 50 km/h in under 20 seconds. The truck uses a tough 7-speed gearbox, proven on 100-ton trucks. This gearbox runs cool, works well, and is simple. The V&T controller automatically picks the right gear for the hill slope and the truck's weight. This keeps the pulling power strong. The truck can climb very steep slopes, over 45%. Even fully loaded, it climbs slopes steeper than 30%. This means it easily handles rough mine terrain.

Foshan, Guangdong recently received a group of new eco-friendly buses. Two hundred brand-new hydrogen fuel buses have been delivered. They will soon run on roads across the Greater Bay Area. These buses use electric motor controllers from Shenzhen V&T Technologies Co., Ltd. (called V&T here). When these buses start operating, they will cut down harmful particles (called PM2.5) in bus exhaust. This helps keep the air fresh in the Greater Bay Area cities. V&T is an important maker of motor controllers for new energy vehicles. They worked closely on this hydrogen bus project. V&T supplied key motor control systems for the buses. This makes sure the buses’ power source works well and reliably. V&T showed strong technical skills. They also delivered parts fast enough to keep up with the bus maker’s production. The bus maker praised V&T for this good work. Right now, all 200 hydrogen buses have their license plates. This means they can soon begin carrying passengers between cities in the Greater Bay Area. Adding these zero-emission buses does more than just update public transport. It’s a solid step toward cleaner air. These buses will truly help reduce PM2.5 levels in our air. They’ll make the air cleaner for cities to "breathe." They’ll help protect the environment we all share.

Recently, a fleet of 18-meter-long pure electric BRT buses equipped with V&T electric vehicle motor controllers has been put into large-scale operation on the main roads of a coastal city. These giants not only practice green and low-carbon concepts through zero emissions but also significantly enhance urban public transport capacity with their efficient and safe operations, effectively alleviating passenger flow pressure during peak hours, becoming an eye-catching new scene on the streets. As urban areas continue to expand, road traffic pressures are increasing day by day. Apart from rail transit, developing Bus Rapid Transit (BRT) systems is becoming an increasingly popular choice for many cities and even an important symbol of modern urban construction. So, what is BRT? BRT, or Bus Rapid Transit, is a new type of high-capacity public transportation method that integrates modern bus technology and intelligent traffic management. It features dedicated roads and modern stations, offering high operational efficiency, often referred to as "metro on the ground." The aim of BRT is to provide convenient passenger services comparable to those of rail transit. The application of this system plays a significant role in improving the efficiency of bus operations and alleviating urban peak hour congestion. Industry observers point out that with more cities promoting the electrification and efficiency of buses, vehicles using V&T electric control solutions are expected to appear in more cities in the future. They will undertake the heavy responsibility of citizens' daily commutes, contributing to the upgrade and image enhancement of the urban transportation network.

Over the past few decades, China's automotive industry has achieved a leapfrog development from scratch to scale, and from weakness to strength. It is now transitioning from being a major player in traditional fuel vehicles to becoming a global leader in electric vehicles. In this transformation, the electrification of public service sectors has played a crucial role, with electric sanitation vehicles emerging as a key direction in the green upgrading of the automotive industry. The successful application of the "Dongfang Hong" series of all-electric sanitation vehicles equipped with V&T electric vehicle motor controllers is making a significant contribution to the sustainable development of urban sanitation in China. Born out of this background, all-electric sanitation vehicles not only achieve zero pollution emissions but also significantly reduce operating costs. As pioneers in this field, YTO Group Corporation continues to strengthen its advantages in traditional sanitation products while consistently increasing investment in R&D for new products. By collaborating with V&T, they are dedicated to developing new energy sanitation equipment that combines high quality, advanced craftsmanship, and environmental sustainability. The "Dongfang Hong" series of all-electric sweepers independently developed by YTO feature V&T electric vehicle motor controllers known for their reliable technology, ranging from 3.7kW to 120kW in power output. These vehicles integrate the functions of both sweepers and high-pressure cleaning vehicles, combining mechanical, electrical, hydraulic, and water systems into one unit. They offer multiple functionalities including road sweeping, scrubbing, high-pressure cleaning, curbstone washing, garbage collection, sewage recovery, spraying, and cleaning of road barriers. The "Dongfang Hong" all-electric sweeper is a new generation of highly efficient outdoor cleaning equipment that achieves "zero pollution," "zero emissions," and "low noise." It continuously contributes to improving urban air quality and creating better living environments for city dwellers. Looking ahead, V&T will continue to drive innovation in electric control technology for sanitation vehicles, providing customers with comprehensive and superior electrification solutions for urban sanitation vehicles, thus making new and greater contributions to the global development of green sanitation services.

Variable Frequency Drives (VFDs) play a crucial role in the operation of cranes and hoists. They are used to precisely control the speed and torque of electric motors, thereby enhancing operational efficiency and control accuracy. On March 16, with the final cable strand accurately positioned, the main cable pulling work for Fenglin Special Bridge on the Xingyi Belt Expressway was successfully completed. This marked a significant milestone in the bridge’s superstructure construction and laid a solid foundation for achieving the goal of full completion by the end of 2020. The high-performance, high-power variable frequency drives (VFDs) provided by V&T Power played an important role in ensuring the smooth progress of the bridge’s main cable installation due to their stable performance and excellent reliability. Fenglin Special Bridge is China’s first large-span steel-concrete composite beam suspension bridge built in mountainous terrain. The vertical height from the bridge deck to the valley floor reaches 364.2 meters—equivalent to approximately 120 stories. The lifting of the prefabricated central crossbeam at Tower No. 4, weighing up to 1,470 tons, set a world record for the heaviest prefabricated concrete component hoisting in mountain canyon bridge construction. Main cable construction is one of the most critical and technically challenging processes in the building of Fenglin Bridge, as it forms the primary load-bearing system of a suspension bridge. The bridge has two main cables—one on each side—each approximately 971 meters long, with a total weight of 4,131 tons. Each single cable consists of 131 strands (including 4 backstays), and each strand is made up of 91 zinc-aluminum-magnesium-coated steel wires with a diameter of 5.45 mm. The maximum weight of a single cable strand is about 16.4 tons. The winch systems installed on both sides of the bridge have extremely high requirements for the performance, stability, and reliability of the VFDs. The V&T V6-H torque vector control VFD performed exceptionally well, playing a key role in the main cable pulling process. Its advanced technology and product stability have received high praise and recognition from users. During equipment commissioning, Ma, a V&T technical engineer, had to walk across the “catwalk” on the bridge. He said: “Standing over 360 meters above the valley floor just thinking about it makes my legs weak. This time really pushed my fear of heights to the limit. Walking on the catwalk feels like walking through clouds—nervous yet incredibly impressive. I deeply admire the hard work, selflessness, and perseverance of the bridge builders, who embody the spirit of the ‘Iron Army.’” Since the start of construction, Fenglin Special Bridge has been widely covered by major media outlets including CCTV's *News Broadcast*, *Morning News*, *Great Transportation of China*, Xinhua News Agency, People's Daily Online, and local...

INVITATON Thailand Manufacturing Expo 2025 Join V&T to experience advanced industrial machinery, automationtechnology, and advanced manufacturing solutions. Booth No.Hall 98-8D20DATE 18th-21st JUNE LOCATION: Bangkok International Trade and Exhibition Centre (BITEC)

V&T’s high-power electric vehicle motor controller has successfully entered the “Roof of the World” in large quantities. The rugged quality of V&T products has been proven in mine sites in Qinghai and Xizang. Recently, 90-ton all-electric wide-body dump trucks equipped with V&T motor controllers have begun operating in high-altitude mining areas in Qinghai (about 4,300 meters above sea level) and Xizang (about 5,000 meters above sea level). This success brings more confidence to China’s new energy vehicle industry and also inspires V&T to keep pushing forward and aiming higher. At a large mine in Xizang, at an average altitude of 5,000 meters, traditional fuel-powered trucks used to carry rock and ore from mountain tops down. In this environment, low air pressure causes poor engine intake, incomplete combustion, reduced power, higher fuel consumption, and greater pollution. Now, a group of energy-saving and eco-friendly 90-ton all-electric wide-body dump trucks has arrived. These vehicles solve the problems of weak power and high fuel cost in high-altitude, low-oxygen conditions. The truck automatically adjusts between single or dual motors based on real-time working conditions through the high-power V&T motor controller. This lowers driver workload, improves efficiency, and helps protect the environment. The dual-motor braking system can recover up to 580 kW of energy, making full use of downhill energy and improving overall economic performance for customers. In these mines, trucks often run heavily loaded downhill for long periods. When the driver brakes, the mechanical energy is turned into electricity by the V&T motor and controller system and stored back into the battery. According to the fleet manager, on a 4.5-kilometer route, each electric truck saves over 2,000 yuan per day compared to fuel trucks—around 25 to 30 trips. Working together with vehicle manufacturers, V&T shows strong reliability under extreme conditions like high altitude and steep slopes. It reflects China’s progress in electric mining trucks and motor control technology. Through real action, V&T supports the mining industry with a new driving force and contributes to greener, safer, and more efficient mining transport.

We are excited to invite you to attend the Metalloobrabotka 2025 exhibition, which will be held from May 26-29, 2024, at the Expocentre Fairgrounds in Moscow, Russia. Booth No:12B25 Date:26th-29th May 2025 Address:EXPOCENTRE FAIRGROUNDS/14,Krasnopresnenskaya nab.Moscow,Russla,123100 Our company, Shenzhen V&T Technologies Co.,Ltd, is a leading supplier of Medium and Low voltage converters, AC drives, motor controllers, elevator products, and other industrial automation solutions. We are committed to providing our customers with high-quality products and services that meet the highest standards of performance, reliability, and efficiency.

A giant mining truck that can generate electricity and make money The advent and successful application of a V&T new energy mining vehicle motor controller has greatly reduced the cost of mining and transportation, and installed a new engine for the development of the mining industry. Wide-body mining vehicles are heavy vehicles used in large open-pit mines to complete rock and earth stripping and ore transportation tasks. They travel back and forth between mining sites and unloading sites, and have the characteristics of short transportation distance and heavy load. Fuel consumption accounts for about 60% to 80% of the total transportation cost. How to control fuel costs has become a key issue in determining the profit and loss of transportation companies. V&T new energy mining vehicle motor controller has been successfully applied in batches to a domestic hybrid "giant" mining vehicle. Its advent and successful application have greatly reduced the cost of mining and transportation, and installed a new engine for the development of the mining industry. The "Big Mac" mining truck is equipped with a V&T motor controller and a four-in-one integrated controller, which integrates drive motor control, oil pump, air pump, high-voltage power distribution, DCDC, brake power generation feedback and charging functions. It has high power density and meets the characteristics of low-speed and high-torque of the drive motor, heavy-load climbing and heavy-load downhill braking power generation requirements, realizing safe and efficient operation under all-weather conditions in different regions. As the depth of open-pit mining increases year by year, the phenomenon of large slopes and multiple bends makes mining operations increasingly difficult. About 50% of a transportation cycle is uphill and 50% is downhill. During the heavy-load downhill braking process, the new energy mining truck uses the V&T motor controller to perform feedback braking and power generation to achieve energy recovery and save energy. The power consumption is about half that of traditional vehicles. There is huge room for future development of electric wide-body mining trucks. V&T is willing to use its excellent wide-body mining truck electronic control solutions and successful application experience to make new contributions to the construction of "green" mines in my country!

INVITATION Dear Valued Client, Shenzhen V&T Technologies Co.,Ltd. cordially invite you to visit our booth [8.1;F18] at the 2025 China Import and Export Fair (Canton Fair) Join us at our booth to explore our latest innovations: VFD, Elevator Inverters, Oil-free Scroll Air Compressors, EV Motor Controllers, Servo Drives, and Solar Inverters. We warmly welcome industry experts for engaging discussions and knowledge exchange. Looking forward to your presence. - Booth Number: [8.1;F18] - Date: April 15th-19th, 2025 - Address: No. 380, Yuejiang Zhong Road, Haizhu District, Guangzhou, China

Recently, Shenzhen V&T Technologies Co.,Ltd.(referred to as V&T) through its investment and strategic partnership with Range Aviation, signed a cooperation agreement with Hainan Huaxia Investment Management Co., Ltd. (referred to as Huaxia Investment) in Haikou, Hainan. The two companies will cooperate on aircraft procurement, cultural and tourism sightseeing, sales, and operations. Huaxia Investment plans to purchase 20 eVTOL aircraft from Rangei Aviation. To date, Range Aviation has received orders for 190 aircraft from four customers. With the recovery of the tourism industry and the rising demand for urban air mobility, Huaxia Investment's partnership with Range Aviation highlights the potential of eVTOL aircraft in the field of cultural and tourism sightseeing. Imagine future tourists enjoying panoramic views of beaches and fishing villages in beautiful Haikou scenic spots via eVTOL aircraft, significantly enhancing their travel experience. The continuous development of urban air mobility technology means that eVTOL aircraft are not limited to cultural and tourism sightseeing. They can also be integrated into areas such as emergency medical services and material transportation, opening up broader market prospects. This trend is attracting widespread global attention. At the end of 2024, Range Aviation's passenger eVTOL model LE200 was fully assembled and delivered in Hefei, Anhui. At the delivery ceremony, important figures including Tang Bin, Party Secretary and Chairman of Anhui General Aviation Holding Group, Li Wei, Deputy Secretary of Baohe District Committee and District Chief, and Dang Hongtie, Founder and Chairman of Range Aviation, were present. The eVTOL LE200 by Range Aviation is designed as a passenger-grade aircraft with a wingspan of 15 meters, body length of 10 meters, maximum take-off weight of 2600 kg, a range of 140-320 kilometers, and a top speed of 200 km/h. It can carry 2 to 5 passengers. After completing the 1:3 scale prototype development and test flights in September 2023, the full-size engineering prototype was put into trial flights. It is expected to obtain type certification by the end of 2027 and be delivered to the market in 2028. The LE200 can be widely used in urban air mobility, low-altitude logistics, medical transfers, emergency rescue, tourism sightseeing, and relay communications. About Range Aviation Hefei Range Aviation Technology Co., Ltd., established in May 2023, is a startup company specializing in the development of Electric Vertical Take-Off and Landing (eVTOL) aircraft. The company focuses on passenger-grade eVTOL technology research, design, manufacturing, and MRO (Maintenance, Repair, and Overhaul). With a team of top professionals in the industry, advanced product designs, efficient R&D progress, and leading commercialization efforts,Range Aviation has become a key player in this field. The LE200 and LE100 models are their main products.Range Aviation and its affiliated companies a...

Celebrating the Lantern Festival with wishes for peace and happiness

Categories