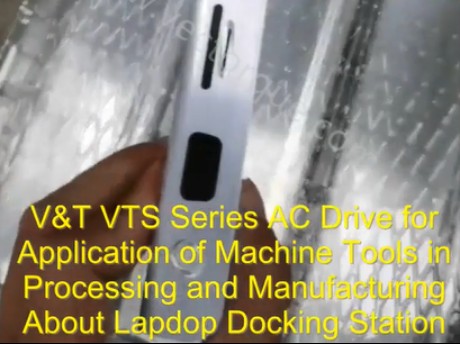

V&T offers a comprehensive CNC machine tool solution featuring high-performance spindle motors and servo spindle drives. With strong compatibility, the system supports various electric spindles, encoders, and communication protocols. It integrates functions such as temperature detection and precision positioning, delivering high stability, efficiency, and cost-effectiveness. The solution is widely compatible with mainstream CNC systems and is extensively used in lathes, machining centers, 5-axis machines, and other precision equipment, ensuring reliable and efficient machining performance.

V&T is proudly showcasing its innovative metal processing and machine tool solutions at METALLOOBRABOTKA 2025, drawing strong attention at Pavilion 1, Booth 12B25. Visit us to experience cutting-edge technology shaping the future of manufacturing.

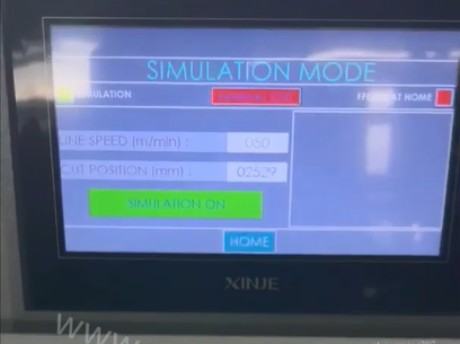

This frequency converter utilizes the Profinet + Siemens 1500PLC communication protocol, enabling seamless integration with the factory automation system. Through the Profinet interface, you can easily communicate with the PLC for real-time data transmission and remote monitoring. This not only enhances the controllability of the production process but also improves the intelligence and automation level of the machinery. The V&T VTS series frequency converter possesses a quick response control capability, allowing for precise control of mechanical movements to ensure product consistency and quality. Its high-performance vector control algorithm enables the frequency converter to adapt to various operational requirements and provide accurate speed and torque control. Consequently, it significantly enhances production efficiency and reliability in the stretching and extrusion machinery within the plastic industry.

Shenzhen V&T products, for your enterprise to improve production efficiency and save more resources! Choose Shenzhen V&TV9 Series products, please contact us in time!