V6-G and V5-G series are special inverter for high performance hoist. The product adopts the torque vector control technology with the current international advanced technology. This product has excellent torque control, reliable brake control on time and sequence, speed monitoring, torque monitoring, power optimization, position processing, intelligent deceleration and other functions.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation:

Express · Sea freight · Land freight · Air freightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShenzhenCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSProduct Overview

| Item | Description |

| Product Name | Frequency Inverter/ AC Drive |

| Model Number | V5/V6-GH-4TxxG, V5/V6-GA-4TxxG |

| Power Range | 0.75kW-500kW |

| Rated Input Voltage | 3 phase 380V/480V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Applicable Motor | Asynchronous Motor |

| Control Mode | V/F Control, Vector Control, Sensor-less Vector Control, Sensor Vector Control, Vector Torque Control |

| Communication | Modbus 485 RTU |

| IP Class | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Feature

■ Perfect combination of PLC and high performance vector inverter on professional crane function

■ Hoist Crane Inverter has strong startup torque under low frequency

■ Reliable brake control to eliminate glide-hook

■ Smooth and reliable lifting speed

■ Greater overload capacity

■ Better power optimization

■ Position processing and intelligent deceleration

■ Standard international bus communication and optimized communication format

■ Safe and sound keyboard operation

■ Comprehensive monitoring and protection with fault

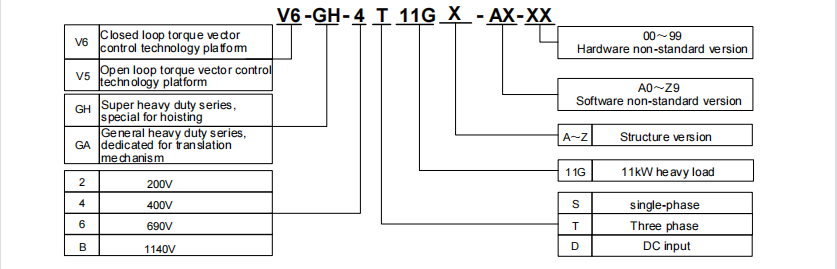

Model Explanation

Product Catalogue

V6−GH−4T□□□G□ and V5−GH−4T□□□G□ ; Three-phase 400V Constant torque/heavy-duty application

Power(kW)

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

Motor power(kW)

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

2.5

3.8

5.5

9

13

17

24

30

39

45

60

75

91

112

150

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

Input

Rated Voltage /frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage range

323V ~ 528V; Voltage unbalance ≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

2.8

4.2

6.1

10

15

19

26

33

43

50

66

83

100

123

165

Braking unit

Built-in as standard

Protection class

IP 20

Cooling mode

Natural cooling

Forced air convection cooling

Power (kW)

75

90

110

132

160

185

200

220

250

280

315

355

400

450

Motor power (kW)

75

90

110

132

160

185

200

220

250

280

315

355

400

450

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

176

210

253

304

350

380

426

470

520

600

650

690

775

860

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

Input

Rated Voltage/frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage range

323V ~ 528V; Voltage unbalance≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

160*

196*

232*

282*

326*

352*

385*

437*

491*

580*

624*

670*

755*

840*

Braking unit

External braking unit needed

Protection class

IP 20

Cooling mode

Forced air convection cooling

*1 0.4~22kW structure version is A, 30~37kW structure version A means the main circuit is DC contactor, B is relay, 45kW and above need not be noted.

*2 0.4 to 55kW standard built-in brake unit, 15kW to 55kW If the brake unit is not required, the model must be equipped with −56, Products with 75kW and above must have an external brake unit.

V6−GA−4T□□□G□ and V5−GA−4T□□□G□ ; Three-phase 400V Constant torque/heavy-duty application

|

Power (kW) |

0.75 |

1.5 |

2.2 |

3.7 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

75 |

|

|

Motor power (kW) |

0.75 |

1.5 |

2.2 |

3.7 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

75 |

|

|

Output |

Voltage (V) |

Three-phase 0 to rated input voltage |

||||||||||||||

|

Rated current (A) |

2.5 |

3.8 |

5.5 |

9 |

13 |

17 |

24 |

30 |

39 |

45 |

60 |

75 |

91 |

112 |

150 |

|

|

Overload capacity |

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

|||||||||||||||

|

Input |

Rated Voltage /frequency |

Three-phase 380V/480V; 50Hz/60Hz |

||||||||||||||

|

Allowable voltage range |

323V ~ 528V; Voltage unbalance ≤3%; allowable frequency fluctuation: ±5% |

|||||||||||||||

|

Rated current (A) |

2.8 |

4.2 |

6.1 |

10 |

15 |

19 |

26 |

33 |

43 |

50 |

66 |

83 |

100 |

123 |

165 |

|

|

Braking unit |

Built-in as standard |

|||||||||||||||

|

Protection class |

IP 20 |

|||||||||||||||

|

Cooling mode |

Natural cooling |

Forced air convection cooling |

||||||||||||||

|

Power (kW) |

90 |

110 |

132 |

160 |

185 |

200 |

220 |

250 |

280 |

315 |

355 |

400 |

450 |

500 |

|

|

|

Motor power (kW) |

90 |

110 |

132 |

160 |

185 |

200 |

220 |

250 |

280 |

315 |

355 |

400 |

450 |

500 |

|

|

|

Output |

Voltage (V) |

Three-phase 0 to rated input voltage |

||||||||||||||

|

Rated current (A) |

176 |

210 |

253 |

304 |

350 |

380 |

426 |

470 |

520 |

600 |

650 |

690 |

775 |

860 |

|

|

|

Overload capacity |

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

|||||||||||||||

|

Input |

Rated Voltage /frequency |

Three-phase 380V/480V; 50Hz/60Hz |

||||||||||||||

|

Allowable voltage range |

323V ~ 528V; Voltage unbalance ≤3%; allowable frequency fluctuation: ±5% |

|||||||||||||||

|

Rated current (A) |

160* |

196* |

232* |

282* |

326* |

352* |

385* |

437* |

491* |

580* |

624* |

670* |

755* |

840* |

|

|

|

Braking unit |

External braking unit needed |

|||||||||||||||

|

Protection class |

IP 20 |

|||||||||||||||

|

Cooling mode |

Forced air convection cooling |

|||||||||||||||

*1 0.7~30kW structure version is A, 37~45kW structure version A means the main circuit is DC contactor, B is relay, 55kW and above need not be noted.

*2 0.7 to 75kW standard built-in brake unit, 18.5kW to 75kW If the brake unit is not required, the model must be equipped with −56, Products with 90kW and above must have an external brake unit.

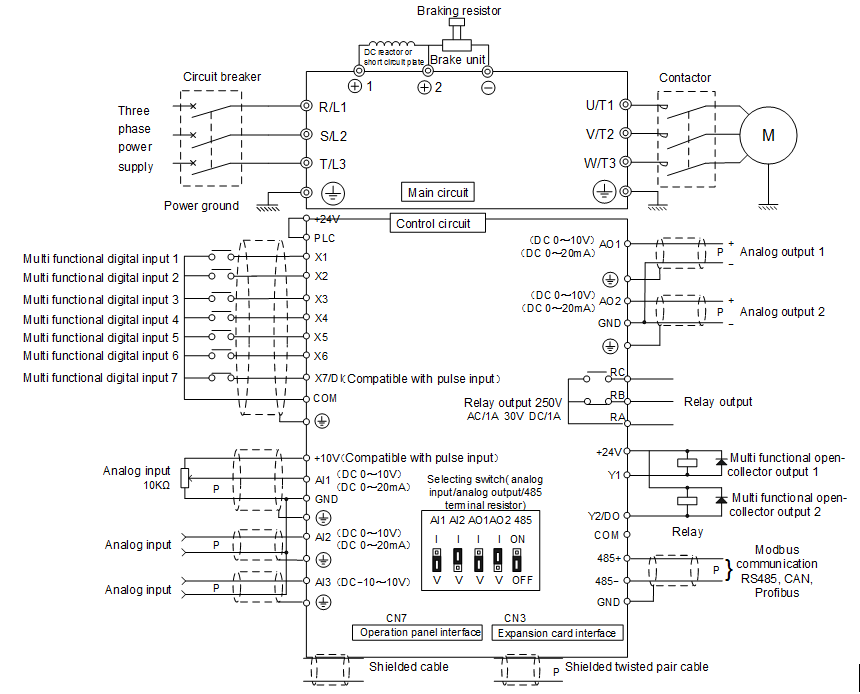

Terminal Wiring diagram

Installation Dimension

|

|

V6/V5−GH−4T5.5G,V6/V5−GA−4T7.5G and below power class

|

|

V6−GH−4T7.5G,V6−GA−4T11G and above power class

Product Appearance, Installation Dimensions, Approximate Weight

|

voltage |

Inverter item |

product outline, mounting dimension(mm) |

weight(kg) |

|||||||

|

W |

H |

D |

W1 |

H1 |

D1 |

T1 |

Install hole d |

|||

|

400V |

V6/V5−GH−4T0.4G V6/V5−GA−4T0.75G |

118 |

190 |

155 |

105 |

173 |

40.8 |

3 |

5.5 |

1.5 |

|

V6/V5−GH−4T0.75G V6/V5−GA−4T1.5G |

118 |

190 |

175 |

105 |

173 |

60.5 |

4 |

5.5 |

2.6 |

|

|

V6/V5−GH−4T1.5G V6/V5−GA−4T2.2G |

||||||||||

|

V6/V5−GH−4T2.2 G V6/V5−GA−4T3.7G |

||||||||||

|

V6/V5−GH−4T3.7G V6/V5−GA−4T5.5G |

155 |

249 |

185 |

136 |

232 |

69 |

8 |

5.5 |

; ;3 |

|

|

V6/V5−GH−4T5.5G V6/V5−GA−4T7.5G |

||||||||||

|

V6/V5−GH−4T7.5G V6/V5−GA−4T11G |

210 |

337 |

200 |

150 |

324 |

107.5 |

2.5 |

7 |

8.5 |

|

|

V6/V5−GH−4T11G V6/V5−GA−4T15G |

||||||||||

|

400V |

V6/V5−GH−4T15G V6/V5−GA−4T18.5G |

285 |

440 |

220 |

200 |

425 |

107.5 |

2.5 |

7 |

17 |

|

V6/V5−GH−4T18.5G V6/V5−GA−4T22G |

||||||||||

|

V6/V5−GH−4T22G V6/V5−GA−4T30G |

||||||||||

|

V6/V5−GH−4T30G V6/V5−GA−4T37G |

315 |

575 |

227 |

220 |

553 |

123.5 |

2.5 |

10 |

25 |

|

|

V6/V5−GH−4T37G V6/V5−GA−4T45G |

||||||||||

|

V6/V5−GH−4T45G V6/V5−GA−4T55G |

400 |

615 |

265 |

270 |

590 |

123.5 |

3.0 |

10 |

35 |

|

|

V6/V5−GH−4T55G V6/V5−GA−4T75G |

||||||||||

|

V6/V5−GH−4T75G V6/V5−GA−4T90G |

465 |

745 |

325 |

343 |

715 |

156 |

3.0 |

12 |

55 |

|

|

V6/V5−GH−4T90G V6/V5−GA−4T110G |

||||||||||

|

V6/V5−GH−4T110G V6/V5−GA−4T132G |

540 |

890 |

385 |

370 |

855 |

205.5 |

4.0 |

14 |

85 |

|

|

V6/V5−GH−4T132G V6/V5−GA−4T160G |

||||||||||

|

V6/V5−GH−4T160G V6/V5−GA−4T185G |

||||||||||

|

V6/V5−GH−4T185G V6/V5−GA−4T200G |

||||||||||

|

V6/V5−GH−4T200G V6/V5−GA−4T220G |

700 |

1010 |

385 |

520 |

977 |

210 |

4.0 |

14 |

125 |

|

|

V6/V5−GH−4T220G V6/V5−GA−4T250G |

||||||||||

|

V6/V5−GH−4T250G V6/V5−GA−4T280G |

||||||||||

|

V6/V5−GH−4T280G V6/V5−GA−4T315G |

810 |

1358 |

425 |

520 |

1300 |

210 |

4.0 |

14 |

215 |

|

|

V6/V5−GH−4T315G V6/V5−GA−4T355G |

||||||||||

|

V6/V5−GH−4T355G V6/V5−GA−4T400G |

||||||||||

|

V6/V5−GH−4T400G V6/V5−GA−4T450G |

||||||||||

|

V6/V5−GH−4T450G V6/V5−GA−4T500G |

||||||||||

Applications

|

|

|

|

|

|

|

|

|

Representative Industry and Applicable Machine

The 3 phase vector control Inverter of Shenzhen V&T Technologies Co.,Ltd. are widely used in Port, Ship, Marine Engineering, Mining, Construction, Metallurgy, Factories and other industries.

Port Wheel Crane, Gantry Crane, Tower Crane, Hoist, Electric Hoist, Crane, Mine Hoist, Winch, Grab Control and other machines.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories