For the energy saving of the injection molding machine, the servo is to realize the closed-loop feedback control, the system dynamic response is fast, and the control precision is high. Servo is the product of inverter development to the advanced stage, and inverter is the mother of servo. The innovation of asynchronous servo cleverly combines the advantages of frequency conversion energy-saving technology and synchronous servo energy-saving technology, while overcoming their respective shortcomings.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation:

Express · Sea freight · Land freight · Air freightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShenzhenCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSProduct Overview

| Item | Description |

| Product Name | Frequency Inverter/ AC Drive |

| Model Number | VY−JY−4TxxG |

| Power Range | 11kW-132kW |

| Rated Input Voltage | 3 phase 380V/480V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Control Mode | V/F Control, Vector Control, Sensorless Vector Control, Vector Torque Control, Sensor Vector Control |

| IP Class | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Feature

■ Hydraulic Motor Drive Easy to install and use, the control mode, oil channel and electric circuit structure of the original equipment does not need to be changed.

■ The driver is provided as standard configuration with an energy saving interface card for the injection molding machine, a standalone flow signal input and a pressure electric signal input, whose signal specifications are: 0~24V/0~2A.

■ Strong current shock resistant capacity and fine vector control feature guarantee continuous, stable and trip-free operation. The Servo Feature Energy Saving Cabinet Inverter can run for 0.5 seconds under 200% loads.

■ Super low speed on-load and quick speed regulating capability, 0.5Hz start torque is 180%, only 0.1 seconds are needed for the motor to accelerate to the rated rotating speed.

■ High power factor output, reactive power loss is lowered, and there is no high current shock under soft start.

■ The performance is great when working together with electric-driven injection molding machine, the output torque is big and accurately positioned under speed sensorless vector control mode.

■ Provide customized technological curve, when the mould is changed, driver parameters do not need to be changed, thus realize the easy memory of technological curve.

■ Wide range torque output, the motor torque output is stable within the setting ranges of pressure and flow, thus guarantee the quality of processed workpiece.

■ State-of-the-art power module driving mode is employed to eliminate the interference to the injection molding machine’s control loop and sensor by the driver.

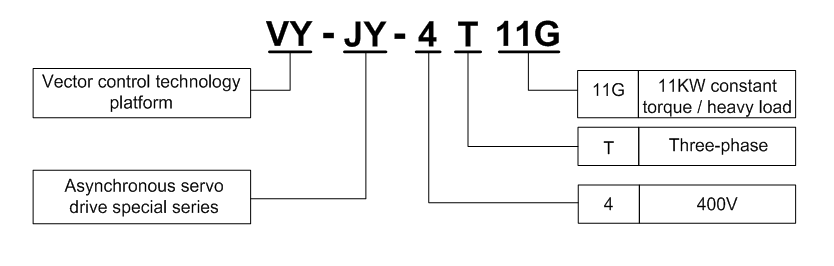

Model Explanation

ProductCatalog

VY−JY−4T□□□G ; Three-phase 400V Constant torque/heavy-duty application

|

Power (kW) |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

75 |

90 |

110 |

132 |

|||

|

Motor power (kW) |

11 |

15 |

18.5 |

22 |

30 |

37 |

45 |

55 |

75 |

90 |

110 |

132 |

|||

|

Output |

Voltage (V) |

Three-phase 0 to rated input voltage |

|||||||||||||

|

Rated current (A) |

24 |

30 |

39 |

45 |

60 |

75 |

91 |

112 |

150 |

176 |

210 |

253 |

|||

|

Overload capacity |

150% ;1 minute, 180% ;10 seconds, 200% ;0.5 second, interval: 10 minutes (inverse time lag feature) |

||||||||||||||

|

Input |

Rated voltage/frequency |

Three-phase 380V/480V; 50Hz/60Hz |

|||||||||||||

|

Allowable voltage range |

323V ~ ;528V; Voltage imbalance≤3%; allowable frequency fluctuation: ±5% |

||||||||||||||

|

Rated current (A) |

26 |

33 |

43 |

50 |

66 |

83 |

100 |

123 |

165 |

160* |

196* |

232* |

|||

|

Braking unit |

Built-in as standard |

Built-in as option |

|||||||||||||

|

Protection class |

IP54(The internal device) |

||||||||||||||

|

Cooling mode |

Natural−cooling |

Forced air convection cooling |

|||||||||||||

Technical Specifications

|

Control features |

Control mode |

Vector control ;1 |

Vector control ;2 |

|

Startup torque |

0.50Hz ;180% |

0.25Hz ;180% |

|

|

Speed adjustment range |

1:100 |

1:200 |

|

|

Speed stabilization precision |

± 0.5% |

± 0.2% |

|

|

Torque control |

N |

Y |

|

|

Torque precision |

- |

±5% |

|

|

Torque response time |

- |

<20ms |

|

|

Product functions |

Key functions |

Undervoltage adjustment, switching of AC operation grounding, protective grounding and DC operation grounding, rotation speed tracing, torque limitation, multi-speed operation (up to 23 speeds),auto-tuning, S curve acceleration/deceleration, slip compensation, PID regulation, drooping control, current limiting control, manual/auto torque increase, current limiting. |

|

|

Frequency setting mode |

Frequency can be set via operation panel,UP/DN ;terminal, or analog inputs of AI1 / AI2/A3, or terminal pulse DI, and can also be set through communication with host computer, ; |

||

|

Frequency range |

0.00 ~ 300.00Hz ; ; ;Note: ;In the control mode of vector control 1 ;0.0 ~ 3000.0Hz,the range ;can be customized according to the customer demand |

||

|

Startup frequency |

0.00~60.00Hz |

||

|

Acceleration/deceleration time |

0.1~36000s |

||

|

Powered braking capacity |

Driver ;of 400V voltage grade: Braking unit action voltage: 650 ~ 750V ;Driver ;of 400V voltage grade: Braking unit action voltage:325 ;~375V ;Operating time: 100.0s The braking unit can beselected ;for VY−H−4T18.5G/22L~ ;VY−JY−4T75G/90L |

||

|

DC braking capacity |

DC braking initial frequency: 0.00 ~300.00Hz; DC braking current:Constant torque: 0.0 ~ 120.0%,Variable torque: 0. 0 ~ 90.0% DC braking time: 0.0 ~ 30.0s; there is no initial waiting time for the DC braking ;torealize ;quick braking |

||

|

Magnetic flux braking function |

Ongoing action and no action upon decelerationasoption, no action upon deceleration at default |

||

|

Unique functions |

Multifunctional M key |

The unique multifunctional key is used to set the frequently used operations: JOG, emergent stop,Running command issuing mode ;switch , menu switching |

|

|

Multiple menu modes |

Basic menu mode, fast menu mode. ;Menu mode of Non-factory setting function codes, Menu mode of last changed 10 function codes |

||

|

Parameter copy |

The standard operation panel can realize the parameter upload, download and display the copy progress. User can select to forbid the overwriting of the uploaded parameters. |

||

|

Displayed/hidden function code |

The customer can select to display or hide the function codes by themselves. |

||

|

Dual RS485 communication ports |

Support Modbus protocol (RTU). The standard operation panel can realizethefunction ;ofremote control box ;with a maximum distance of 500m. |

||

|

Operation panel |

Button type or shuttle type operation panel optional, protection class: IP20 as standard, IP54 as option |

||

|

Shared DC bus |

The full series can realize shared DC bus supply for several drivers. |

||

|

Independent duct |

The full series adopts independent duct design and supports the installation of heatsink outside the cabinet |

||

|

Universal expansion interface |

Universal expansion board equipped with CPUfor ;supporting customers secondary development: physical interface ;SPI bus, software protocol ;Modbus |

||

|

Expansion card |

User’s secondary development card, injection molding ;machine interface card, PG feedback card, air compressor control card,communication adapter card,power monitoring card, phase sequence detection card, external power rectifying card |

||

|

Power-upauto-detection |

Realizing the power-upauto-detection of internal and peripheral circuits, including motor grounding, abnormal +10V power supply output, abnormal analog input, and disconnection |

||

|

Protection function |

Power supply under-voltage, over-current protection, over-voltage protection, interference protection, abnormal comparison reference input,auto-tuning ;failure, module protection, heatsink over-temperature protection, driver overload protection, motor overload protection, peripheral protection, abnormal current detection, output to ground short circuit, abnormal power failure during operation, abnormal input power, output phase failure, abnormal EEPROM, relay suction pull-on anomaly,temperature sensor taking sample anomaly, encoder disconnection, abnormal +10V power supply output, abnormal analog input, motor over-temperature (PTC), abnormal communication, abnormal version compatibility, abnormal copying, abnormal expansion card connection, terminal mutual exclusion detection failure, hardware overload protection |

||

|

Efficiency |

At rated power, 7.5kW and below power class ≥93%, 45kW and below power class ≥95%, 55kW and above power class ≥98% |

||

|

Environm-ent |

Operating site |

The driver shall be mounted vertically in the electric control cabinet with good ventilation. Horizontal or other installation modes are not allowed. The cooling medium is the air. The driver shall be installed in the environment free from direct sunlight, dust, corrosive gas, combustible gas, oil mist, steam and drip. |

|

|

Ambient temperature |

-10 ~ +40ºC, derated at 40 ~ 50ºC, the rated output current shall be decreased by 1% for every temperature rise of 1ºC |

||

|

Humidity |

5 ~ 95%, no condensing |

||

|

Altitude |

0 ~ 2000m, derated above 1000m, the rated output current shall be decreased by 1% for every rise of 100m |

||

|

Vibration |

3.5mm,2~9Hz; 10 m/s2,9~200Hz; 15 m/s2,200~500Hz |

||

|

Storage temperature |

-40~+70ºC |

||

Motor Wiring

It is forbidden to short circuit the Servo-driven Hydraulic Machine VFD output terminals or short circuit to ground, otherwise the internal components of the variable frequency inverter will be damaged.

Do not short circuit the output cable to the universal variable frequency drive enclosure, otherwise electric shock may happen.

It is forbidden to connect the output terminal of the inverter to the capacitor or LC/RC noise filter with phase lead, otherwise, the internal components of the inverter may be damaged.

When contactor is installed between the inverter and motor, it is forbidden to switch on/off the contactor when the V&T Vfd Drive is running; otherwise, large current will flow into the industrial inverter, triggering the inverter protection action.

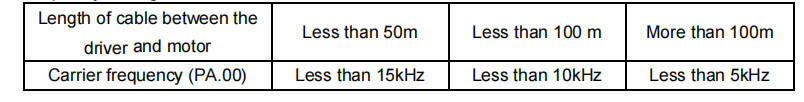

Length of cable between the 3 Phase Frequency Converter and motor. If the cable between the frequency inverter and the motor is too long, the high−order harmonic leakage current of the output end will cause adverse impact on the Single Phase To 3 Phase Inverter Converter and the peripheral devices. Output AC reactor should be installed if the motor cable is longer than 100m, Refer to the following table for the switching frequency setting.

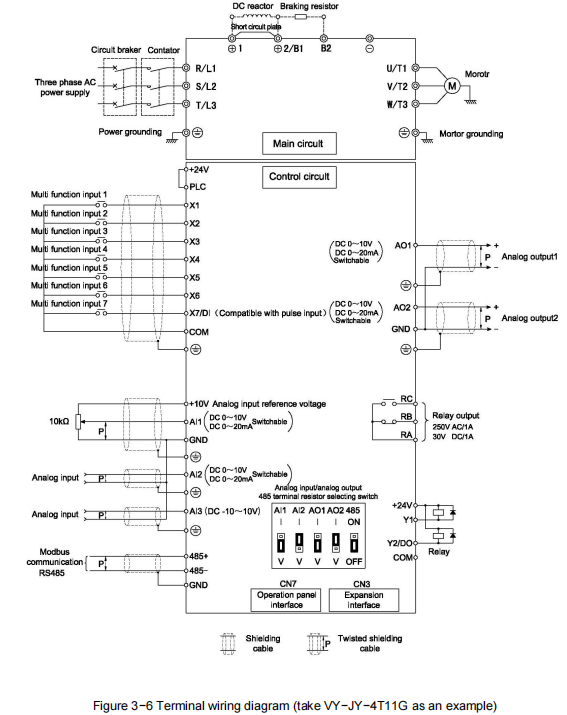

Terminal Wiring Diagram

Installation dimension

|

|

11KW~75KW power class

|

|

90KW and above power class

Product outline, mounting dimension, and weight

|

Voltage class |

Driver model |

Outline and mounting dimension (mm) |

Approximate weight (kg) |

|||

|

W |

H |

D |

H1 |

|||

|

400V |

VY−JY−4T11G |

300 |

605 |

240 |

523 |

20 |

|

VY−JY−4T15G |

||||||

|

VY−JY−4T18.5G |

350 |

712 |

270 |

630 |

34 |

|

|

VY−JY−4T22G |

||||||

|

VY−JY−4T30G |

||||||

|

VY−JY−4T37G |

380 |

867 |

316 |

785 |

47 |

|

|

VY−JY−4T45G |

||||||

|

VY−JY−4T55G |

450 |

972 |

316 |

890 |

65 |

|

|

VY−JY−4T75G |

||||||

|

VY−JY−4T90G |

500 |

1575 |

500 |

1400 |

165 |

|

|

VY−JY−4T110G |

||||||

|

VY−JY−4T132G |

||||||

Applications

|

|

|

|

|

|

|

|

|

Energy Saving Drive VFD Representative Industry

As an advanced China Hydraulic Drive System Manufacturers,The use of V&T frequency drive (VFDs): a VFD is used to regulate the speed and torque of the Motor according to the variation of the load in order to improve the Motor energy efficiency. The technology of AC-VFD-AC drives power overcomes the small range and poor speed adjustment performance. Shenzhen V&T Technologies Co.,Ltd. AC servo drives is suitable for Injection Molding Machine Motor Drive, Air compressor, Die casting machine speed drive, Energy-saving industry etc.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories