V&T Inverter In Machine Tool Industry

I. Product Description

V5 and V6 series inverter are high performance vector control inverter. The speed-sensorless vector control technology synchronous with currently international leading technology is adopted for product,which is not only provided with the same excellent control performance as international high-end frequency converter, but also combines application characteristics,further intensifying the product reliability and environmental adaptability.

V&T inverter with large torque upon low frequency and rapid acceleration and deceleration, realizes fast response and applies to application characteristics of machine tool industry,satisfying processing technic demand of machinery device and improving processing efficiency.

II. Industry lectotype and advantage

Industry lectotype

The advanced speed-sensorless vector control technology is adopted for V5 and V6 series frequency converter. Under open loop vector control,0.25HZ can provide 180% startup torque and ±0.2% speed stabilizing accuracy. Under closed loop vector control,0Hz can provide 180% startup torque and ±0.02% speed stabilizing accuracy. It can attain quite quick response speed for spindle motor to realize its quick start and quick stop. Especially for motor running at lower frequency,its rapidity in start and stop is more evident.

V5 – H series inverter with vector control 1 and vector control 2 control mode, should be selected for general machine tool to perform workpiece processing, with stable and large cutting force.

The rigidity tapping and other thread processing industries require high processing velocity accuracy and large tapping force. V6–H inverter is adopted as an actuating mechanism; it can commendably satisfy demands of such industries.

For high speed engraving and milling machine with running frequency exceeding 300HZ, V5–H–H3 Inverter drive for high-speed engraving and milling machine should be adopted, which support maximum output frequency up to 3200Hz.

When machine performs high-speed engraving and milling or boring for PCB board,spindle speed is stable, wouldn’t be in off tracking and fall speed, which greatly improves the qualification rate of the machined products.

It requires extremely large torque and no stalling when machine tool cutting workpiece at low frequency. The V6–H series inverter should be selected and encoder is needed to perform closed loop vector control mode. Under close loop vector control, the speed stabilizing precision is 10 times than the open loop vector control mode,satisfying the machine spindle processing requirement at low frequency and heavy cutting.

V6–H–M0 series products realize orientation angle, 8 angles at most when select by terminal. If more than 8 angles are required, it can be realized by communication to satisfy technics demands of different machining. Under 0Hz running status, spindle accurately stays at the correct angle. The spindle keeps very large torque without changing spindle angle.

V6-H-M1 series spindle inverter can realize simple positioning control function and satisfy the application of certain special high-end industry.

V6 – H series standard products output frequency up to 300HZ. If output frequency exceeds 300Hz under close loop vector control, V6–H–M3 series nonstandard products which output frequency up to 500Hz should be selected; it can also realize orientation at arbitrary angle, satisfying more extensive speed adjustable range of machine tool.

Industry advantage

|

Large torque at low frequency |

Compared with similar brands,it is provided with larger cutting force and cutting depth, can improve efficiency and productive capacity. |

|

Fast response |

With faster acceleration and deceleration time,it can attain 0.1 seconds at the soonest and improve machine tool production efficiency |

|

Stable speed |

Under open loop vector control,its speed stabilizing accuracy can attain 0.2% and can effectively improve machining accuracy |

|

Excellent current and voltage limit ability |

With super strength anti-sudden shock and overload abilities, it is provided with precise current loop control. During shock load or power grid fluctuation and other external disturbances,the inverter is not easy to trip out for protection, which can better ensure continual stable operation of production equippments. |

|

Compact design |

With compact conformation, it is suitable especially for being assorted with machine tool, saving cost and improving the product competitiveness |

|

Simple servo function |

Orientation at arbitrary angle, and the angle is accurate |

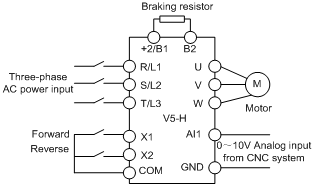

III. Wiring Diagram under Open Loop control for CNC system

IV. Function code setting

First, the motor should be disconnected from the load, and input the motor parameters to perform rotating parameter auto-tuning. After auto-tuning, the parameters should be set as below:

|

P0.03=4 vector control 2 without encoder speed feedback |

|

P0.04=1 Speed reference through analog AI1 |

|

P0.06=1 Running command reference through terminal |

|

P0.08=1 Acceleration time is 1 second |

|

P0.09=1 Deceleration time is 1 second |

|

P0.11=187 Maximum output frequency is 187 Hz |

|

P0.13=187 Frequency upper limit is 187 Hz |

|

P3.09=0 Reverse running is enable |

|

P5.00=2 X1 terminal function is forward |

|

P5.01=3 X2 terminal function is reverse |

|

P5.02=20 X3 terminal function is reset |

|

PA.09=1 Braking unit is enable |

|

Pd.33=0 Torque limiting compensation coefficient of constant power zone is 0 |

V. Contrast result with certain international brand under open loop vector control

|

Inverter brand |

Startup time |

Stopping time |

|

Inverter of certain international brand |

7 seconds |

6.8 seconds |

|

V&T inverter |

5 seconds |

3.2 seconds |

Note:The above test time is time for spindle to accelerate from o to 4000rpm and decelerate from 4000rpm to 0, the motor running frequency of 200Hz and externally connected braking resistor of 1.8kW. 50Ω.

Ⅵ.Epilogue

V&T CNC VFD Inverter quickly grows up on CNC application with its preeminent performance and superhigh cost-effective, can completely replace international brand and even represent out higher performance than international brand. It can not only come up to requirement of custom system, but also save customer cost and create more benefit for customer.

Previous :

V&T Inverters In Spinning-frame IndustryNext :

Mine lifting machine