AC Drives VFD Classifications

AC drives or Variable frequency drives control speed, torque, acceleration, deceleration, and rotation direction of AC motors. AC drives save energy by tailoring the power delivered to meet the actual load requirements. AC drives replace mechanical gearboxes, belts, hydraulic couplings, DC drives, servo-drives, or eddy current drives in many situations. AC drives provide an accurate and wide range of smooth and step-less control of motor speed and torque in a highly efficient, low maintenance, compact size package. AC drives also provide versatile built-in functions, complex control, and networking capabilities and freedom from mechanical inertia and resonance. For AC drives, Pulse Width Modulated (PWM) technology is the primary industry standard.

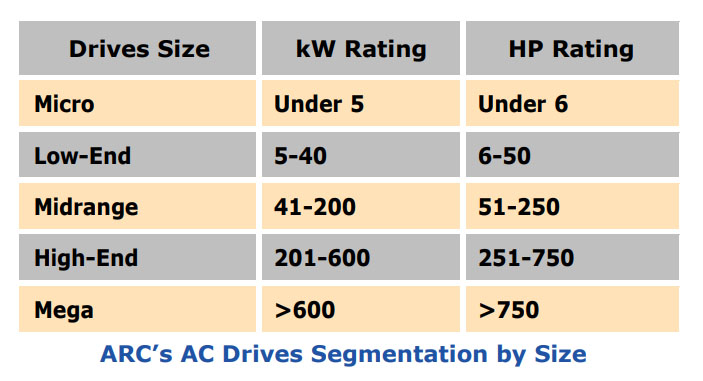

AC Drives or Variable Frequency Drives Classification by Size

ARC has segmented the AC drives market into five size ranges as defined by the drives’ output kilowatt and horsepower ratings. While ARC’s low power AC drives global market research study includes micro, low-end, and midrange drives, ARC’s high power AC drives global market research study includes the midrange, high-end, and mega drives markets. ARC has included midrange AC drives in both the low power and high power market studies.

Many AC drives models have a very wide operating power range. For example, some suppliers offer a variation of the same model of AC drives that operates from low to high power ranges. Suppliers may offer a range of products that fall into multiple segmentations. Since such models can span different kilowatt segmentations, ARC has allocated the sales of these drives into their single most appropriate segmentation to avoid double counting. When AC drives are mounted on motors, this study only accounts for the drives portion, based on its appropriate AC drives type.

Low Power AC Drives Classification by Control Mode

Volts/Hertz (Hz), the traditional mode of motor control, prevents motor magnetic saturation by maintaining a constant volts/Hz ratio. At low speeds, the low voltage supplies less magnetizing current, leading to a loss of torque. Another limitation is that volts/Hz control does not correct for variation in slip between the rotor and stator with frequency and load. Suppliers that sell mechanical power transmission products with low power AC drives typically provide gears and belts to address low speed torque requirements.

Modes of control that overcome the limitations of volts/Hz control are closed loop flux vector control and open loop sensorless vector control . With the former, a sensor, such as an encoder on the motor shaft, provides a measure of slip for speed control. With the latter, a built-in current sensor (external sensors are absent) provides information for control. In both cases, the low power AC drives compensates for slip and magnetization current needs based on an internal software model of motor characteristics, but the feedback is either from the external encoder or the built-in current sensor. These modes require tuning for effects, such as the time delays of high-inertia loads. Auto-tuning drives address this requirement without manual intervention. In addition to tracking shipments by modes of control, this study also includes multi-mode drives that support two or more modes of control.

Low Power AC Drives Classification by Input Voltage

Input voltage is a distinguishing feature of low power AC drives because the power delivered varies substantially with the voltage. As a result, the classification of low power AC drives by voltage in this study considers the following main ranges: 115V to 240V, 380V to 400V, 460V to 480V, and 560V to 690V.

Low Power AC Drives Classification by Bus Configuration

Low power AC drives convert an AC input into DC to generate the required output voltage and frequency. For applications involving a large number of low power AC drives (such as conveyors or synthetic fiber manufacturing), there are drives designed for a single large DC power supply, known as a Common DC bus. This reduces costs and better utilizes regenerative braking energy compared to independent drives. This segmentation helps provide a better understanding of the trend towards using a common bus configuration.

AC Drives by Hardware, Software, and Services

ARC segments the low power AC drives market in terms of hardware (drives hardware and peripheral hardware), software and services (including project services and MRO/spares and services) to better convey the market characteristics. “Drive Hardware” is low power AC drives as standalone units. It includes preprogrammed features and functions, as well as programmable options.

As users of low power AC drives focus on core competencies, they increasingly rely on suppliers of low power AC drives to provide services. In addition to training, installation and commissioning services, users expect single point accountability or turnkey project management, application engineering and custom software development to adapt the AC drives to their own needs. Users of low power AC drives also expect supplier-initiated maintenance and upgrade programs to protect their investments

Previous :

About Variable Frequency Drive (VFD)Next :

Inverter IntroductionCategories

New Blog