AFE Drive Systems: Regenerative Power & 4-Quadrant Control Solutions

In industrial production, the efficient and stable operation of speed control systems is paramount. Traditional systems often face challenges like low power factor, difficulty in energy regeneration, and significant harmonic interference, constraining production efficiency and quality. Active Front End (AFE) technology provides an effective solution to these issues.

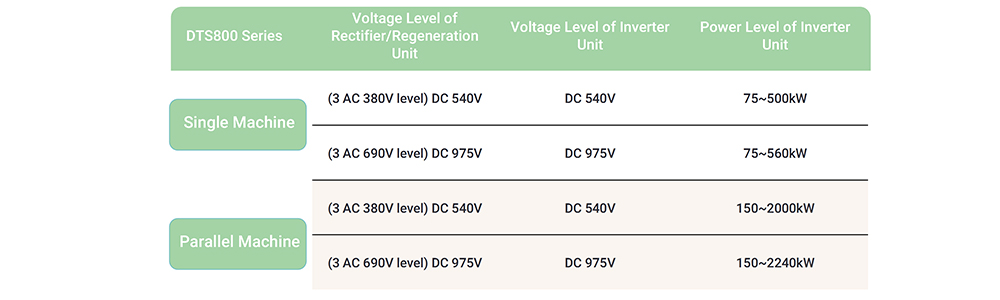

V&T's DTS800 Series AFE products are designed precisely to meet the demands of high-performance speed control. An AFE is a drive unit that supplies DC power to a variable frequency drive (VFD) via PWM rectification while simultaneously regenerating braking energy from the motor back to the grid. Together with the motor drive section, it forms a complete AFE speed control system, enabling four-quadrant operation for motor-driven speed regulation.

DTS800 Series Core Components:

DTS800-R AFE Rectifier/Regeneration Module:

DTS800-H Drive Inverter Module:

Wide Application Scope:

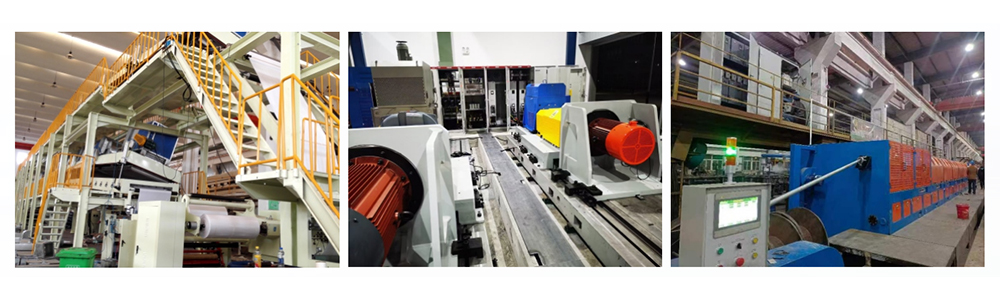

The DTS800 Series AFE products are ideally suited for applications requiring stable power supply and efficient regeneration of motor braking energy to the grid, including:

Crane equipment, centrifugal equipment, oilfield equipment, experimental test platform, opposite drive system, downhill conveyor belt, winch.

The V&T DTS800 Series AFE products demonstrate solid and reliable characteristics across key aspects: four-quadrant operation capability, energy regeneration efficiency, control algorithm implementation, ease of use, communication support, and structural design. Their robust and high-performance nature precisely meets the stringent requirements of modern industrial production for speed control systems while aligning with industry trends.

Previous :

How does a VFD enhance the mine hoist?Next :

Can a VFD run multiple motors?