As the VFD manufacturer in china, V&T has rich experience in electric drive fields. V&T V9−H Series General Purpose Inverter is a high-performance vector control and torque controlled frequency drive. Vector control technology and torque control technology are employed. It can better meet the needs of various transmission applications.Voltage range covers 200V, 400V, 690V, and 1140V. The product power range covers 0.4kW to 3MW.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation:

Express · Sea freight · Land freight · Air freightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShenzhenCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGS

Product Overview

Item

Description

Product Name

Frequency Inverter/ AC Drive

Model Number

V9-H-4TxxG/xxL

Power Range

0.75kW-630kW

Rated Input Voltage

3 phase 380V/480V

Rated Output Voltage

3 phase 0 to rated input voltage

Input Frequency

50Hz/60Hz

Applicable Motor

Asynchronous Motor, Synchronous Motor

Control Mode

V/F Control, Vector Control, Sensorless Vector Control, Sensor Vector Control, Vector Torque Control

Communication

Modbus 485 RTU, CANOpen, Profibus-DP, Profinet

IP Class

Standard IP20

Overload Capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

Feature

■ Fast and accurate motor parameter self-learning, suitable for a variety of motors: synchronous/asynchronous/reluctance/high-speed/torque motor, VF vector encoder closed loop integrated

■ 220V 380V Inverter VSD Asynchronous and non-inductive VF control, 200% torque output at 0.25Hz in electric state, 200% torque output at 1Hz in power generation state

■ Good voltage and current control, high speed, high frequency, deep field weakening, wave-by-wave current limiting, multiple protections

■ Modular compact structure design, high power density

■ Support multiple encoders and multiple high-speed communication protocols

■ Integrated drive and control, expandable PLC and motion control card

■ Multiple language keyboard, friendly interface, reliable and easy to use

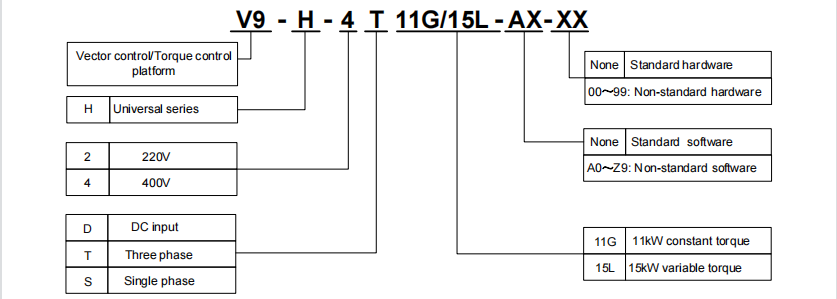

Model Explanation

Product Catalogue

V9−H−4T□□□G Three-phase 400V constant torque / heavy duty Application

Power(kW)

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

Motor power (kW)

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

Output

Voltage (V)

3-phase 0 -rated input voltage

Rated current (A)

2.5

3.8

5.5

9

13

17

24

30

39

45

60

75

91

112

150

176

210

Overload capability

150% 1 min,180% 10 s, 200% 0.5 s,10 min interval (Inverse-time characteristic)

Input

Rated voltage / frequency

3-phase 380V-480V; 50Hz/60Hz

Allowable voltage

323V-528V; degree of voltage unbalance:≤3%; allowable frequency fluctuations:±5%

Rated current (A)

2.8

4.2

6.1

10

15

19

26

33

43

50

66

83

100

123

165

194

231

Brake unit

Standard built-in

Built-in brake unit is optional

Protection level

IP 20

Cooling method

Self−cooling

Forced cooling

Power(kW)

132

160

185

200

220

250

280

315

355

400

450

500

560

630

Motor power (kW)

132

160

185

200

220

250

280

315

355

400

450

500

560

630

Output

Voltage (V)

3-phase 0 -rated input voltage

Rated current (A)

253

304

350

380

426

470

520

600

650

690

775

860

950

1100

150% 1 min,180% 10 s, 200% 0.5 s,10 min interval (Inverse-time characteristic)

Input

Rated voltage / frequency

3-phase 380V-480V;50Hz/60Hz

Allowable voltage

323V-528V; degree of voltage unbalance:≤3%; allowable frequency fluctuations:±5%

Rated current (A)

232

282

326

352

385

437

491

580

624

670

755

840

920

1050

Brake unit

External braking unit needed

Protection level

IP 20

Cooling method

Forced cooling

Note:

0.75kW~15kW:No built-in DC reactor ;

18.5kW~110kW:Optional DC reactor ;

132kW~160kW:Standard built-in DC reactor ;

185kW~500kW:Standard external DC reactor;

560kW~630kW:Standard built-in AC input reactor;

Higher power level product can be customized

220V, 690V, 1140V and other voltage level inverters can be customized.

V9−H−4T□□□L Three−phase 400V Variable torque/light−duty Application

Power(kW)

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

Motor power (kW)

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

Output

Voltage(V)

3-phase 0 -rated input voltage

Rated current (A)

3.3

5

7.5

11

17

22

29

35

45

57

70

91

110

144

180

216

242

Overload capability

120% 1min,160% 0.5s,10min interval (Inverse-time characteristic)

Input

Rated voltage /frequency

3-phase 380V-480V; 50Hz/60Hz

323V-528V; degree of voltage unbalance:≤3%; allowable frequency fluctuations:±5%

Rated current (A)

3.6

5.5

8.3

12

19

25

32

39

50

61

77

100

121

158

198

238

266

Brake unit

Standard built-in

Built-in brake unit is optional

Protection level

IP 20

Cooling method

Self−cooling

Forced cooling

Power(kW)

160

185

200

220

250

280

315

355

400

450

500

560

630

710

Motor power (kW)

160

185

200

220

250

280

315

355

400

450

500

560

630

710

Output

Voltage (V)

3-phase 0 -rated input voltage

325

365

405

440

495

547

610

695

770

866

950

1100

1200

1300

Overload capability

120% 1 min,160% 0.5 s,10 min interval (Inverse-time characteristic)

Input

Rated voltage /frequency

3-phase 380V-480V; 50Hz/60Hz

323V-528V; degree of voltage unbalance:≤3%; allowable frequency fluctuations:±5%

Rated current (A)

282

326

352

385

437

491

580

670

755

840

920

1050

1150

1250

Brake unit

External braking unit needed

Protection level

IP 20

Cooling method

Forced cooling

Note:

1.5kW - 18.5kW: No built-in DC reactor ;

22kW~132kW: Optional DC reactor ;

160kW~185kW: Standard built-in DC reactor ;

200kW~560kW: Standard external DC reactor ;

630kW~710kW: Standard built-in AC input reactor;

Higher power level product can be customized ;

220V, 690V, 1140V and other voltage level inverters can be customized.

Technical Specification

|

Control characteristics |

Control mode |

Sensor-less control |

Sensor control |

|

Applicable motor type |

Synchronous motor Asynchronous motor |

Synchronous motor Asynchronous motor |

|

|

Starting torque |

● Asynchronous motor: 200% of rated torque at 0.25Hz ● Synchronous ;motor: 150% of rated torque at 1.5% of rated speed

|

200% of rated torque at 0 speed |

|

|

Speed regulation range |

1:200 |

1:5000 |

|

|

Steady speed precision |

± 0.5% |

± 0.02% |

|

|

Maximum speed |

VF control: 600 Hz Vector control: 600 Hz

Note: Higher frequency products can be customized |

600 Hz Note: Higher frequency products can be customized |

|

|

Torque control |

Y |

Y |

|

|

Torque control precision |

±5% |

±3% |

|

|

Torque response time |

<20 ms |

<10 ms |

|

|

Positioning control |

N |

Y |

|

|

Positioning precision |

N |

±1 pulse |

|

|

Product function |

Key function |

Torque limit, speed control, positioning control, motor auto tune, deep flux-weakening control, current limit control, over-voltage control, under-voltage control, motor speed tracing function, droop control, oscillation suppression, random carrier frequency, inertia auto-tune, etc. |

|

|

Speed reference source |

Modbus communication, Keypad, external digital input, analog AI1/AI2/AI3, high speed pulse input, simple PLC, PID, CAN, PROFIBUS DP, PROFINET, etc. |

||

|

Dynamic brake |

Brake unit action voltage: 650 ~ 750V. The brake unit can be built-in for 110kW and below equipment ● 0.75~15kW: brake unit is built- in as standard. ● 18.5~110kW: brake unit is built- in as optional. |

||

|

Communication |

Built-in Modbus-RTU communication, the maximum distance up to 500 meters. |

||

|

Keypad |

LED Keypad and LCD Keypad are optional the Keypad can be used as remote-control box via straight-through wired cable. |

||

|

Common DC bus |

Support common DC bus directly |

||

|

Independent air duct |

All series product adopts independent duct design |

||

|

Protection function |

Power supply under-voltage, over-current protection, over-voltage protection, auto-tune fault, module protection, heat-sink over-temperature protection, drive overload protection, motor overload protection, peripheral protection, current abnormal detection, output short-circuit to ground protection, EEPROM abnormal detection, temperature sampling disconnection, encoder disconnection, analog input abnormal detection, motor over-temperature, communication fault, hardware overload protection, etc. |

||

|

Efficiency |

At rating condition: ● 0.75kW to 7.5kW: ≥ 93% ● 11kW to 45kW: ≥ 95% ● 55kW and higher power class: ≥ 98% |

||

|

Environment |

Operating site |

● Install vertically in a well-ventilated electrical cabinet. Horizontal or other installation methods are not allowed. ● The cooling medium is air. ● Installed in an environment free from direct sunlight, dust, corrosive gases, flammable gases, no oil mist, no steam, no dripping. |

|

|

Ambient temperature |

● −10~+40℃ ● Derating use when the temperature between 40 to 50℃, the rated output current is reduced by 1% for every 1 °C increasing. |

||

|

Humidity |

5~95%, no condensation is allowed. |

||

|

Altitude |

● 0~2000 meters ● Derating use when the altitude over 1000 meters, the rated output current is reduced by 1% for every 100-meter rising. |

||

|

Vibration |

● 3.5 m/s2, 2~9Hz ● 10 m/s2, 9~200Hz ● 15 m/s2, 200~500Hz |

||

|

Storage temperature |

−40~+70℃. |

||

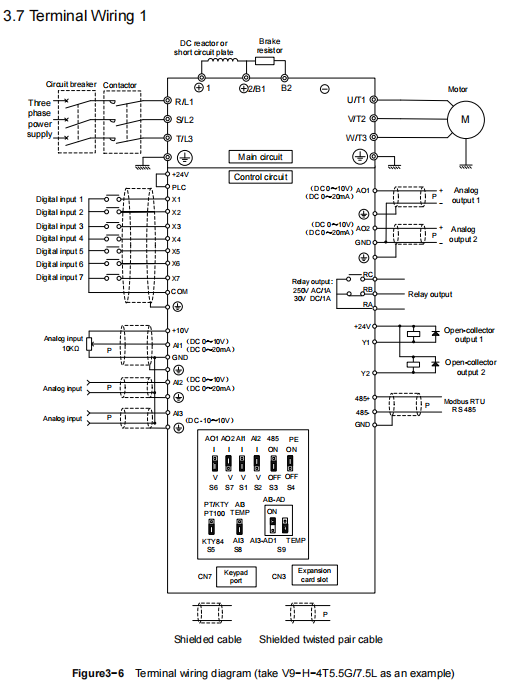

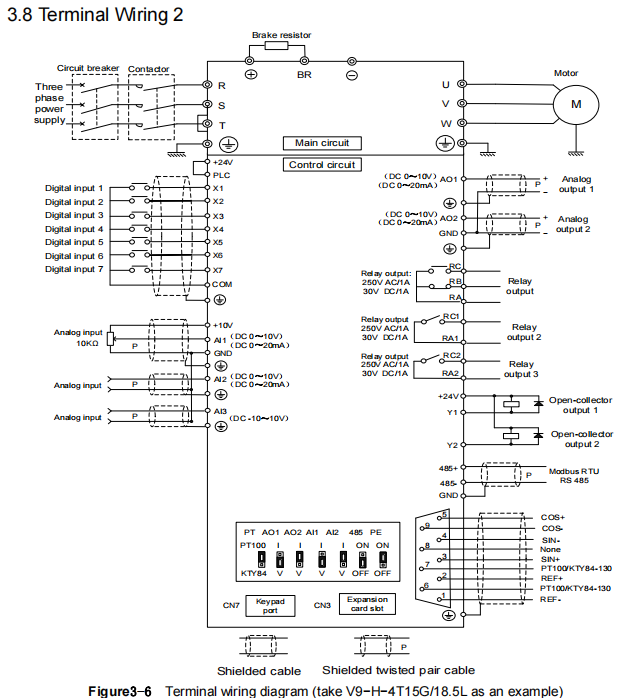

Motor Wiring

Short circuit or grounding of the AC to DC Converter output terminals is prohibited. Otherwise, it will cause damage to the internal components of the drive.

Avoid output cables (U/V/W) short circuit or short circuit to enclosure, otherwise there is a risk of electric shock.

It is strictly forbidden to connect a capacitor or phase lead LC/RC noise filter to the output of the AC Converter Drive, otherwise the drive will be damaged.

When a contactor is installed between the V&T Inverter and the motor, the switching action of the output contactor cannot be performed during the operation of the drive, otherwise a large current will flow into the drive to and the drive will report fault information.

Cable length between drive and motor: When the cable between the RS485 Modbus Frequency Drive and the motor is too long, the high-order harmonic leakage current at the output will adversely affect the drive and peripheral devices. It is recommended to install a output AC reactor when the motor cable exceeds 100 meters, and contact the manufacturer to inquire whether the carrier frequency needs to be modified.

Installation dimension

|

|

V9−H−4T7.5G/11L and below power class

|

|

V9−H−4T11G/15L and above power class

|

Voltage |

Model |

Outline and mounting dimension (mm) |

Weight (kg) |

||||||

|

W |

H |

D |

W1 |

H1 |

T1 |

Mounting hole diameter d |

|||

|

400V |

V9−H−4T0.75G/1.5L |

118 |

190 |

155 |

105 |

173 |

3 |

5.5 |

1.5 |

|

V9−H−4T1.5G/2.2L |

118 |

190 |

175 |

105 |

173 |

4 |

5.5 |

2.6 |

|

|

V9−H−4T2.2G/3.7L |

|||||||||

|

V9−H−4T3.7G/5.5L |

|||||||||

|

V9−H−4T5.5G/7.5L |

155 |

249 |

185 |

136 |

232 |

8 |

5.5 |

3 |

|

|

V9−H−4T7.5G/11L |

|||||||||

|

V9−H−4T11G/15L |

198 |

299 |

190 |

160 |

283 |

1.2 |

6 |

8 |

|

|

V9−H−4T15G/18.5L |

|||||||||

|

V9−H−4T18.5G/22L |

223 |

348 |

208 |

195 |

335 |

1.5 |

6 |

10 |

|

|

V9−H−4T22G/30L |

|||||||||

|

V9−H−4T30G/37L |

264 |

430 |

235 |

230 |

418 |

1.5 |

7 |

18 |

|

|

V9−H−4T37G/45L |

|||||||||

|

V9−H−4T45G/55L |

305 |

545 |

270 |

245 |

523 |

1.5 |

10 |

35 |

|

|

V9−H−4T55G/75L |

|||||||||

|

V9−H−4T75G/90L |

338 |

580 |

310 |

270 |

560 |

1.5 |

10 |

52 |

|

|

V9−H−4T90G/110L |

|||||||||

|

V9−H−4T110G/132L |

|||||||||

|

V9−H−4T132G/160L |

400 |

917 |

323 |

320 |

890 |

3.0 |

12 |

75 |

|

|

V9−H−4T160G/185L |

|||||||||

|

V9−H−4T185G/200L |

540 |

890 |

385 |

370 |

855 |

4.0 |

14 |

85 |

|

|

V9−H−4T200G/220L |

|||||||||

|

V9−H−4T220G/250L |

540 |

890 |

416 |

370 |

855 |

4.0 |

14 |

85 |

|

|

V9−H−4T250G/280L |

700 |

1010 |

385 |

520 |

977 |

4.0 |

14 |

125 |

|

|

V9−H−4T280G/315L |

|||||||||

|

V9−H−4T315G/355L |

700 |

1010 |

418.5 |

520 |

977 |

4.0 |

14 |

125 |

|

|

V9−H−4T355G/400L |

810 |

1358 |

425 |

520 |

1300 |

4.0 |

14 |

215 |

|

|

V9−H−4T400G/450L |

810 |

1358 |

425 |

520 |

1300 |

4.0 |

14 |

215 |

|

|

V9−H−4T450G/500L |

|||||||||

|

V9−H−4T500G/560L |

|||||||||

Applications

|

|

|

|

|

|

|

|

|

Representative Industry

As an Automation & Control Systems Provider and Inverter Drive Manufacturer, AC drives are used to bring about process and quality improvements in industrial and commercial applications' acceleration, flow, monitoring, pressure, speed, temperature, tension, and torque. Whenever a load has either a variable torque or a variable speed, a VFD should be considered to control torque and speed. V9 series universal speed AC drive of Shenzhen V&T Technologies Co.,Ltd. is suitable for CNC VFD Drives, Printing Packaging, Petrochemical, Textile, Cable Machinery, Food Packaging, Electric Vehicles, Plastic Machinery, Metal Products Equipment, Centrifuges and High-end applications requiring closed-loop vector or torque control.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories