DTS800 series drive, driven by DTC control technology, is a multi-drive AC Inverter developed independently by V&T Company. With fast torque response performance and higher speed stability accuracy, DTC control can be realized with or without encoder. Even without encoder, the unique DTC control technology, with characteristics of large torque at low frequency and fast torque response, can meet application requirements in most cases.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 Working Days For Standard Series; 7-14 Working Days For Customized AC DrivesTransportation:

Express · Sea Freight · Land Freight · Air FreightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShenzhenCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGSProduct Overview

| Item | Description |

| Product Name | Multi-Drive AC Inverter |

| Model Number | DTS800-H-4TxxG-AX-XX |

| Power Range | 75kW-500kW |

| Rated Input Voltage |

AC220V DC320V AC400V DC540V AC690V DC980V |

| Rated Output Voltage | 3 phase 0 to rated input voltage |

| Input Frequency | 50Hz/60Hz |

| Applicable Motor | Asynchronous Motor |

| Control Mode | Scalar Control, DTC Control Without Encoder, DTC Control With Encoder |

| Communication | Modbus 485 RTU, CANopen, Profibus-DP, CAN |

| IP Code | Standard IP20 |

| Overload Capacity | 150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature) |

Features

1. Adopt the independently developed DTC control technology with stronger robustness and fast torque response.

2. Adopt the common DC bus connection mode. Multi-Drive Inverter has the advantages of simple installation, convenient connection, reducing control cabinet space and saving energy consumption. This largely saves the wiring, installation and maintenance costs.

3. Built-in buffer circuit, no need for additional buffer circuit and directly powered by DC power supply.

4. Wide coverage of power levels, up to 3000kW in parallel voltage.

5. Wide voltage level coverage with three levels, respectively corresponding to 3AC220V, 3AC380V and 3AC690V for rectifier.

6. Full series of LCD operating panels by default (optional Chinese/English language).

7. Commission and monitor visa a browser without installing PC software and inserting rich built-in application macros.

8. Customized programming function, convenient commissioning and flexible application.

9. Support changing to active rectification unit.

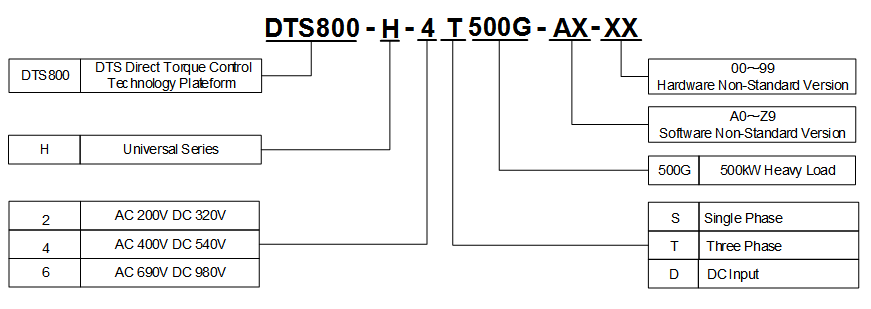

Model Explanation

Product Catalogue

DTS800-H−4T□□□G DC540V Constant Torque/Heavy Load Application

Power (kW)

75

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Motor power (kW)

75

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated Current (A)

150

176

210

253

304

350

380

426

470

520

600

650

690

775

860

Max Current (A)

270

317

378

455

547

630

684

765

846

936

1080

1170

1242

1395

1548

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

Input

Rated Voltage

DC540V

Braking unit

Built-in as option

External braking unit

Protection class

IP20

Cooling mode

Forced air cooling

Note: 75kW~200kW: optional built-in brake unit.

If larger power is needed, the machine can be paralleled, with a maximum of 4 parallel machines, and the maximum power is 500*4=2000kW.

If lower power is needed, choose the VTS series single-drive product. And It supports AC input and DC input. For details, see introductions of the VTS series product or VTS30 series product.

Technical Specifications

|

Control characteristics |

Control Mode |

Scalar Control |

No-encoder DTC Control |

DTC Control With encoder |

|

Starting torque |

0.50Hz 150% |

0Hz 100%;0.25Hz 200% |

0.00Hz 200% |

|

|

Speed regulation range |

1:100 |

1:200 |

1:1000 |

|

|

Steady speed precision |

± 0.5% |

± 0.2% |

± 0.02% |

|

|

Torque control |

No |

Yes |

Yes |

|

|

Torque control precision |

— |

±5% |

±3% |

|

|

Torque response time |

— |

<20ms |

<10ms |

|

|

Product function |

Key function |

Under-voltage regulation, switchover of run command source(operation panel, terminal and communication), speed tracing function, torque limit, multi− step frequency reference, motor data identification, S curve acceleration and deceleration,Mechanical brake control, PID regulation, droop control, current limit, Torque/speed control mode switching, user load curve, master-slave control, user-defined programming, AFE rectifier feedback. |

||

|

Speed reference source |

Parameter setting, operation panel UP/DN, terminal, terminal UP/DN, communication, analog, more combinations. |

|||

|

Frequency range |

0.00~600.00Hz |

|||

|

Starting mode |

Automatic startup, speed tracking startup, automatic DC excitation startup, constant time DC excitation startup |

|||

|

Acceleration time and deceleration time |

Multiple acceleration and deceleration times, and S-curve acceleration and deceleration modes can be set |

|||

|

Dynamic braking |

With overload capacity estimation |

|||

|

DC braking |

DC braking function does not required waiting time to start to realize quick braking |

|||

|

Magnetic flux braking |

Activate and cancel options, and do not act when decelerating by default |

|||

|

Unique functions |

Keypad |

Standard LCD operation panel |

||

|

Browser adjusting |

No special upper computer monitoring software is required, and you can directly use the browser to adjust on the computer |

|||

|

Multi IO terminal |

Up to 13 digital inputs and 6 relay outputs |

|||

|

Multiple parameters display modes |

User parameters, monitoring parameters, non factory value parameters |

|||

|

Parameters copy |

The standard operation panel can realize the parameters upload, download |

|||

|

Dual 485 communication ports |

Dual 485 communication ports support Modbus protocol (RTU). The maximum distance is 500 meters |

|||

|

Common DC bus |

All series product support common DC bus |

|||

|

Independent duct |

All series product adopts independent duct design and supports the installation of heat-sink outside the cabinet |

|||

|

Power-On-Self-Test (POST) |

Realizing the POST of internal and peripheral circuits, including motor grounded, abnormal +10V power supply output, analog input and disconnection, etc. |

|||

|

user-defined programming |

It does not need a computer, and can realize the user-defined programming function, and can encrypt the user-defined programming |

|||

|

AFE active rectifier |

Rectification feedback function can be realized |

|||

|

Protection function |

Power supply under-voltage, over-current protection, over-voltage protection, interference protection, abnormal comparison level, motor data identification failure, module(IPM) protection, heat-sink over temperature protection, inverter overload protection, motor overload protection, peripheral protection, abnormal current detection, output short circuit to ground, interruption of power supply when in running status, abnormal input power, output phase loss, abnormal EEPROM protection, abnormal pre-charging contactor detection, temperature sampling disconnection, encoder disconnection, abnormal analog input, motor over temperature protection(PTC), abnormal communication, hardware overload protection, over-speed protection and other protection functions. |

|||

|

Efficiency |

At rated power: 75kW and above power class ≥98% |

|||

|

Environment |

Operating site |

The product should be mounted vertically in the electric control cabinet with good ventilation. Horizontal or other installation modes are not allowed. The cooling medium is the air. The product should be installed in the environment without dust, corrosive gas, combustible gas, oil mist, steam, drip and free from direct sunlight |

||

|

Ambient temperature |

−10 to +40ºC, the product must be de-rated rated output current for the ambient temperature between 40ºC to 50ºC, the rated output current must be de-rated for 1% per 1ºC temperature rise |

|||

|

Humidity |

5 to 95%, no condensing |

|||

|

Altitude |

0 to 2000m, the product must be de-rated rated output current for the altitude above 1000 meters, the rated output current must be de-rated for 1% per 100 meters rise |

|||

|

Vibration |

3.5 m/s2,2~9Hz;10 m/s2,9~200Hz;15 m/s2,200~500Hz |

|||

|

Storage temperature |

-40~+70℃ |

|||

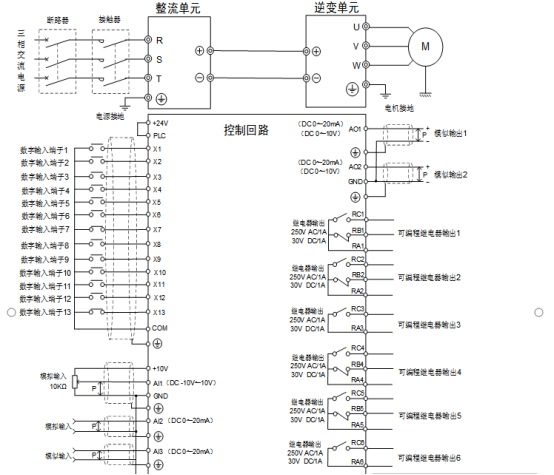

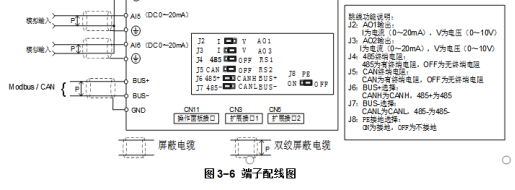

Functions of Control Circuit Terminals

| Type | Terminal | Description | Technical specification |

| Modbus/CAN | BUS+ | RS485+ /CANH | Modbus:Rate: 4800/9600/19200/38400/57600bps |

| Up to 32 sets of equipment can be paralleled. Relay shall be used if the number exceeds 32 | |||

| Maximum distance: 500m | |||

| CAN:Max rate 1Mbps | |||

| BUS− | RS485− /CANL | Select 485 or CAN communication by jumper | |

| GND | Modbus/CAN Communication Ground | Internal isolated with COM | |

| Operation pane Modbus | CN11 | RS485 port of operation panel | The upper computer communication connection is the same as the terminal 485 |

| The maximum distance between the operation panel and the operation panel interface is 15 meters (standard twisted shielded network cable) | |||

| Digital input | +24V | +24V |

24V±10%, internal isolated with GND Maximum output current: 200mA, with overload and short circuit protection |

| PLC | Power supply of multi−function input terminal | Short circuited with +24V by default | |

| X1~X13 | Multi−function input terminals 1 ~ 13 | Input specification: 24VDC,5mA | |

| Frequency range: 0 ~ 200Hz | |||

| Voltage range: 24V±20% | |||

| COM | Ground terminal for +24V | Internal isolated with GND | |

| Relay output | RA1/RB1/RC1 | Relay output | RA1−RB1:normally closed |

| RA1−RC1:normally open | |||

| Contact capacity:250VAC/1A,30VDC/1A | |||

| RA2/RB2/RC2 | Relay output | RA2−RB2:normally closed | |

| RA2−RC2:normally open | |||

| Contact capacity:250VAC/1A,30VDC/1A | |||

| RA3/RC3 | Relay output | RA3−RC3:normally open | |

| Contact capacity:250VAC/1A,30VDC/1A | |||

| RA4/RB4/RC4 | Relay output | RA1−RB1:normally closed | |

| RA1−RC1:normally open | |||

| Contact capacity:250VAC/1A,30VDC/1A | |||

| RA5/RB5/RC5 | Relay output | RA2−RB2:normally closed | |

| RA2−RC2:normally open | |||

| Contact capacity:250VAC/1A,30VDC/1A | |||

| RA6/RC6 | Relay output | RA3−RC3:normally open | |

| Contact capacity:250VAC/1A,30VDC/1A | |||

| Analog input | +10V | Analog input reference voltage | 10V ±3%,Internal isolated with COM |

| Maximum output current: 10mA, with short circuit and overload protection | |||

| AI1 | Analog input channel 1 | -10V~10V,input impedance 20kΩ,Resolution: 12 bits(0.025%) | |

| AI2~AI5 | Analog input channel 2~5 | 0~20mA:input impedance 500Ω | |

| GND | Analog ground terminal | Internal isolated with COM | |

| Analog output | AO1 | Analog output 1 | 0~20mA:allowable output impedance 200~500Ω |

| 0~10V :allowable output impedance ≥10kΩ,Output precision 2%,Resolution: 10 bits(0.1%) with short circuit protection | |||

| 0 ~ 20mA or 0 ~ 10V output can be selected by jumper | |||

| AO2 | Analog output 2 | Same AO1 | |

| GND | Analog ground terminal | Internal isolated with COM |

Note: * If the user can adjust the potentiometer indirectly at+10V and GND, the resistance of the potentiometer should not be less than 5k Ω.

Terminal Wiring

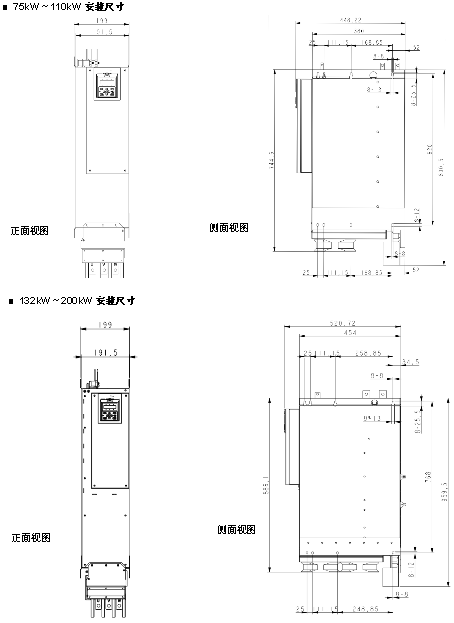

Installation Dimension

Installation Dimension

|

Voltage |

Model |

Outline and mounting dimension (mm) |

weight (kg) |

||||||

|

W |

H |

D |

W1 |

H1 |

T1 |

⌀d |

|||

|

AC 400V

DC 540V |

DTS800−H−4D75G |

199 |

800 |

448 |

− |

620 |

7.5 |

− |

− |

|

DTS800−H−4D90G |

|||||||||

|

DTS800−H−4D110G |

|||||||||

|

DTS800−H−4D132G |

199 |

959.5 |

520.5 |

− |

768 |

7.5 |

− |

− |

|

|

DTS800−H−4D160G |

|||||||||

|

DTS800−H−4D185G |

|||||||||

|

DTS800−H−4D200G |

|||||||||

|

DTS800−H−4D220G |

247 |

1485 |

459.5 |

− |

1414.5 |

− |

− |

− |

|

|

DTS800−H−4D250G |

|||||||||

|

DTS800−H−4D280G |

|||||||||

|

DTS800−H−4D315G |

|||||||||

|

DTS800−H−4D355G |

260 |

1585 |

576.5 |

160 |

1516.5 |

− |

− |

− |

|

|

DTS800−H−4D400G |

|||||||||

|

DTS800−H−4D450G |

|||||||||

|

DTS800−H−4D500G |

|||||||||

Optional Accessories/Expansion Card

|

Item |

Name |

Model |

Function Explanation |

|

Operation panel Pallet |

Pallet |

VTS−DP05 |

Mounting accessories of operation panel |

|

Extensible Card |

PG Feedback Card |

EX−PG01 |

Power supply +12~24V, open collector, push pull type encoder feedback card, maximum current 200mA, up to 80K pulse input. |

|

EX−PG03 |

Power supply +12~24V, open collector, push pull type encoder feedback card, maximum current 200mA, up to 80K pulse input, with frequency division output. |

||

|

EX−PG20 |

Power supply +12~24V, open collector, push pull type encoder feedback card, maximum current 200mA,up to 80K pulse input,with two relays output. |

||

|

EX−PG02 |

Power supply +5V, differential type encoder feedback card, maximum current 150mA, up to 300K pulse input. |

||

|

EX−PG04 |

Power supply +5V, differential type encoder feedback card, maximum current 150mA, up to 300K pulse input, with frequency division output. |

||

|

EX−PG21 |

Power supply +5V, differential type encoder feedback card, maximum current 150mA, up to 300K pulse input, with two relays output. |

||

|

Relay extensible card |

EX−PG22 |

two relays output. |

|

|

Communication module of CANopen slave station |

EX−CA04 |

CANopen DS301、DS303、DS305 protocol Installation method: internal and external |

|

|

Profibus−DP communication adapter card |

EX−CA06 |

Installation method: internal and external |

|

|

communication adapter card |

EX−CA13 |

ProfiNet Industrial Ethernet communication, with 5V incremental encoder interface and frequency division output. Installation method: Internal |

|

|

Keypad extension cable |

2 meters keypad extension cable |

CB1−200 |

2 meters keypad extension cable |

|

3 meters keypad extension cable |

CB1−300 |

3 meters keypad extension cable |

Applications

|

|

|

|

|

|

|

|

|

DTC Control Drive Inverter Representative Industry

It is suitable for motor-driven applications in all walks of life, including 690V AC Drive, DC 540V Input Inverter, fans, water pumps, lifting equipment, printing equipment, paper-making equipment, belt conveyor, etc. especially for applications in process industries such as the pulp, metals, mining, cement, power, chemical, and oil & gas industries.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2024 Shenzhen V&T Technologies Co.,Ltd.. All Rights Reserved. Power by

IPv6 network supported