From March 1 to March 3, 2017, the annual Guangzhou International Industrial Automation Technology and Equipment Exhibition (SIAF) was held in Guangzhou Pazhou Complex. As a professional media agency in the field of industry, CAISG not only presented its solutions with the integrated solutions for the automation industry, but also exhibited with the well-known partners such as Shenzhen V&T Technologies Co.,Ltd. V&T is a state-level high-tech enterprise with complete independent intellectual property rights. It specializes in the research, manufacture, sales and service of electric and electronic drive products such as motor controllers, frequency converters/Frequency drive/VFD/VSD/Inverter and servo drives for electric vehicles. It won the "2012 EV Prize for Technology Excellence" jointly awarded by China Electrotechnical Society, Electric Vehicles Committee, China Society of Automotive Engineers, and EV Branch. It won the "Technology Innovation Award" from the Inverter Industry Association. The most competitive among the China Electro-technical Society Force own-brand "award and many other awards, the company successfully listed on the GEM in 2016. Shenzhen V&T Technologies Co.,Ltd. focuses on product innovation and research and development, with the core motor drive control technology, while improving the industrial design and production platform, the new energy electric vehicle motor controller has a rich and complete product line: synchronous / asynchronous main drive motor control ISG and BSG motor controller, pump / pump motor controller and other stand-alone standard series and customization of combo, triple and multi-integrated products dozens of models, power coverage 3kW-280kW; and by With a number of system assembly manufacturers, component manufacturers and vehicle manufacturers in close cooperation, as of now has more than 110,000 main motor controller and auxiliary motor controller supporting a number of major domestic OEMs all kinds of battery electric or hybrid Application on the car. At the exhibition site, CAISG showed visitors the superior performance of different product lines of V&T, and attracted the attention and consultation from many domestic and foreign buyers. Up to now, V&T has won the sincerity of some buyers, some buyers have reached an initial contact with the cooperation intention. For Shenzhen V&T Technologies Co.,Ltd. Shenzhen V&T Technologies Co.,Ltd. is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a “National Hi-tech enterprise” and “Double-software enterprise”, which has fully intellectual property rights and devotes to the R&D, manufacture, sales and technical service of Frequency Inverter(Variable frequency drive) , Servo Drives, Electric Vehicle Motor Controller(E-Drive), Solar pump inverter ,etc.. V&T has won the “Technical Innovation” prize awarded by Inverter(AC Drive) Industry Association (I...

Shenzhen V&T Technologies Co.,Ltd. New Book-style AC Drive Three groups of high-speed chip communication interface Support extension CPU development; Support development of function extension card for industrial machine; Support the secondary application and development of customers to the hardware and software; Shenzhen V&T Technologies Co.,Ltd is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a “National Hi-tech enterprise” and “Double-software enterprise”, which has fully intellectual property rights and devotes to the R&D, manufacture, sales and technical service of Frequency Inverter(Variable frequency drive) , Servo Drives, Electric Vehicle Motor Controller(E-Drive), Solar pump inverter ,etc.. V&T has won the “Technical Innovation” prize awarded by Inverter(AC Drive) Industry Association (IIA), the “The most competitive VFD brands” prize awarded by China Electrical Association, “Electric Vehicle Excellent Technology” Prize awarded by China Electro-Technical Society (CES). V&T has been ranked as one of the Top 10 Chinese Inverter(frequency drive) Enterprises. Shenzhen V&T Technologies Co.,Ltd. has completely grasped the key control technique and also possesses the capacity of industrialization design and manufacturing. It has developed lots of product series. The product voltage grade mainly contains 200V, 400V, 690V, 1140V, and the power grade varies from 0.4kW to 3000kW, which could meet various application demands from high, medium and low level market. Shenzhen V&T Technologies Co.,Ltd. established in 2006, the headquarters located in Shenzhen, We have 600+ staff, 200 of them are R&D engineers. All the products have it’s own IPRs. The investment to R&D is more than 10% of turnover per year. As a industry leader in China, V&T’s products and industry solution are recognized for its quality, reliability and cost-efficiency in an ever-increasing number of markets worldwide. We are committed to being the world's leading and most respected ;industrial control systems provider to deliver the high grade and competitively priced products in the market. So far V&T drive control products have been exported to over 60 countries like Korea, Germany, England, Russia, UAE, Pakistan, Thailand, India, Australia, South Africa, Mexico etc.

China has gradually become the world's manufacturing center for the inverter in the industrial automation applications has brought rapid growth, the global energy shortage is to bring long-term demand for the inverter industry, inverter in recent years more than 15% growth rate and will continue to show this momentum, the inverter has a vast market opportunities. From the current domestic inverter accounted for only about 25% of the market share point of view, any one of the basic industries in the proportion of national brands will be higher and higher, as industrial products, although not as home appliances and other consumer goods industry brands can account for 70% More than the market share, but in the near future domestic inverter occupy half of the market share is expected. With this projection, the domestic frequency inverter in the next few years there will be several times the size of the growth, this is an absolute good and opportunity. However, opportunities always coexist with challenges. In the inverter's two main applications: 1, the field of industrial automation, most of the needs of this area is medium and low power inverter, its performance and system requirements are higher and higher and constantly updated, made in China If you can not continue to improve and synchronize with the development of industrial demand, it is possible to become a bystander rather than a participant in the progress of industrial automation. It is even more difficult to seize the share of foreign brands. 2, while in the field of energy saving, the main demand is medium and high power frequency converters, which provide stable and reliable products with different voltage levels of general purpose, medium voltage and high voltage. Technology is also the core foundation. Therefore, in order to seize the opportunity and change the current inverter in China, "foreign brands to eat dinner, domestic brands drink porridge," the dilemma of technological innovation, breakthroughs and continuous improvement is the core issue, but also made higher for domestic brands Requirements and challenges. Only with technological advances and leading in order to make the product meet the rising demand for high-end applications, perfect combination with the market and participate in the competition of international brands, so that the real rise of domestic inverter brand. Casting industry with the international quality products Although it is a very young company, Shenzhen V&T Technologies Co.,Ltd. has more than 20 years of research and development of VFD technology and accumulated industry experience. Facing the opportunities and challenges of the inverter, the company established its own technological superiority at the beginning of its establishment, Cast industry quality as the goal to meet the opportunities and face the challenges. Through continuous innovation and breakthroughs, the company already has the vector control technology and torque control technology syn...

As we know, VFD drive play a major and very important role in nowadays. It can help the world life more comfortable and sustainable. Variable Frequency Drive for short can called VFD, other names can also called AC Drive, Frequency Inverter, Frequency Converter, adjustable speed drive, adjustable frequency drive, variable speed drive and microdrive. A VFD drive is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Shenzhen V&T Technologies Co.,Ltd. Is specialized in low voltage variable speed drive and medium voltage frequency drive, pumping unit controller, servo drive and electric vehicle drive. The name of V&T means Vector and Torque control, it also express Victory and Trust. V&T has completely grasped the key control technique and also possesses the capacity of industrialization design and manufacturing. It has developed a lot of variable speed drive series. V&T self-develop variable frequency drives covering voltage level 200V, 400V, 690V, 1140V and power rating is from 0.4KW to 3000KW. Under the premise of meeting the demand for international standards and satisfying different industrial application, we further strengthened the product reliability and environmental adaptability to suit harsh and extreme environments. V&T variable frequency drive are widely used in metallurgy, crane, oil, chemicals, machine tools, electric vehicles, metal processing, building materials, stone, wood processing, ceramics, plastics, air compressor, washing machine, water supply, air conditioning, municipal engineering, textile, printing, mining and other industries. Shenzhen V&T Technologies Co.,Ltd. main frequency drive series: E5 series high performance universal vector control variable speed drive Voltage degree: 220V, 380V, 690V, 1140V Power range: 0.4KW~3000KW E5-H series is a high performance universal vector control variable frequency drive with superior performance ratio and powerful control functions. This series widely used in various VFD drives and speed regulation used for machine tools, food processing industry, paper making industry, metallurgy industry, chemical industry, wire and cable industry, power industry, textile and transmission industry. It’s overload capacity, 150% in one minute, 180% in 10 seconds, 200% in 0.5 second. E5-H-4T90G and higher power products are equipped with external DC reactor as standard. V5 series high performance vector control frequency drive Voltage degree: 220V, 380V, 690V, 1140V Power range: 0.4KW~3000KW V5-H series is a high-performance vector control variable speed drive. The product has open-loop vector control technology which is completely synchronized with the most advanced technology in the world. It has excellent control performance with the international high-end VFD drive. And it is combined with the use characters of China, and the reliability and environmental adaptability of the products are further str...

Hardware E5 V5 V6 Digital input terminal X1~X4 X1~X7/DI X1~X7/DI Support DI input NO YES YES Digital putput terminal 1(Y1) 2(Y1 and Y2/DO) 2(Y1 and Y2/DO) Relay 1(RA-RB-RC) 1(RA-RB-RC) 1(RA-RB-RC) Analog 2(AI1 and AI2) 3(AI1、AI2、AI3) 3(AI1、AI2、AI3) Analog input support +10V~-10V NO YES(AI3) YES(AI3) Analog output 2 2 2 Support DO output NO YES(Y2/DO) YES(Y2/DO) Support dual 485 NO (*) YES YES Support operation panel 485 YES YES YES Support extension card NO(*) YES YES Support built in braking unit 15kw and below power built in as standard. 15kw and below power built in as standard. 15kw and below power built in as standard. Other power class only support external braking unit. 18.5kW~75kW braking unit can be optional. 18.5kW~75kW braking unit can be optional. 90kW and above only support external braking unit 90kW and above only support external braking unit (*)Note:If E5 series need terminal 485 or support extension card, should order non-standard control board. Vector control 1 without encoder speed feedback P0.03=0 YES YES YES P0.03=1 YES YES YES P0.03=2 NO YES YES P0.03=3 NO YES YES Vector control 2 without encoder speed feedback P0.03=4 NO YES YES P0.03=5 NO YES YES P0.03=6 NO YES YES P0.03=7 NO YES YES Vector control 2 with encoder speed feedback P0.03=8 NO NO YES P0.03=9 NO NO YES P0.03=10 NO NO YES P0.03=11 NO NO YES Torque control Torque control without encoder NO NO YES Torque control with encoder NO NO YES Other Default braking voltage 750 720 720 X1/X2 terminal delay YES NO NO Y1 terminal and relay delay and pulse width setting YES NO NO Pump and fan control YES NO NO Sleep and wake up YES NO NO Acceleration and deceleration time auto switch YES NO NO View user continuous running time YES NO NO View user total running time YES NO NO Output if continuous running time arrive YES NO NO Output if total running time arrive YES NO NO Force energy saving rate setting YES NO NO Force waking up YES NO NO Output sleeping status YES NO NO PID function YES YES YES Setting pressure reference Mpa YES NO NO Statis auto-tuning YES YES YES Rotating auto-tuning NO YES YES For Shenzhen V&T Technologies Co.,Ltd. Shenzhen V&T Technologies Co.,Ltd. is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a “National Hi-tech enterprise” and “Double-software enterprise”, which has fully intellectual property rights and devotes to the R&D, manufacture, sales and technical service of Frequency Inverter(Variable frequency drive) , Servo Drives, Electric Vehicle Motor Controller(E-Drive), Solar pump inverter ,Integrated elevator drive etc.. V&T has won the “Technical Innovation” prize awarded by Inverter(AC Drive) Industry Association (IIA), the “The most competitive VFD brands” prize awarded by China Electrical Association, “Electric Vehicle Excellent Technology” Prize awarded by China Electro-Technical Society (CES). V&T has been ranked as one of the Top 10 Chinese Inverter(frequency...

I. Technics Introduction The spinning-frame is main spinning machine. The yield and quality of spun yarn comprehensively reflects merits and shortcomings of each working procedure in spinning process. The spinning-frame's production unit is spindle. The yield (kg) per thousand spindle hour is frequently used to measure production-level of spinning-frame. The spinning mill's production scale is represented by total spindles of spinning-frame. The spinning yarn on each spindle would be broken for all kinds of reasons. The end breakage rate is frequently represented by number of broken ends per thousand spindle hour. The end breakage rate affects labour productivity, equipment productivity, spun yarn quality and workshop dust content. The spinning-frame is a machine with the most dissipation energy in spinning. Decreasing end breakage rate and energy saving is a technical level mark of spinning-frame. The textile inverter is rich in application experience in spinning industry,especially in spinning-frame industry. Through multiyear research,V&T understands each process flow and launches the dedicated inverter special for spinning-frame. Its technics features are as follows: a.Small yarn stage occupies 15% of total length,but end breakage rate is about 70%. The speed at small yarn stage can be decreased appropriately according to yarn status so as to decrease end breakage rate. b. Middle yarn stage occupies 80% of total length. The end breaking is extremely few,occupying around 10%. The motor speed can be increased appropriately at this stage so as to improve efficiency. c. Large yarn stage occupies 5% of total length. The end breaking is 20%. The motor rotation speed can be decreased appropriately at large yarn stage to decrease end breakage rate and improve the product quality. The technics curve control at multistage speeds can be performed for frequency converter according to spinning-frame features. The running schematic diagram is shown in Fig. 1. Fig. 1 Running schematic diagram of spinning-frame It can be known from Fig. 1 that low speed running of frequency inverter is effective at initial period and frequency speed drive outputs low speed running command; After low speed running command is cancelled,the frequency converter runs according to a curve set by multistage speed technics. The frequency converter accelerates to multistage speed 1 for running. Along with increase of the first stage length,frequency gradually increases. After running of the first stage length is completed,frequency converter runs at multistage speed frequency 2. This process changes at uniform speed; Each section yarn length setting is increased in sequence. The parameter design can be set from full yarn length commencement,gradually decreasing each section length setting. Each section length is limited by the next section length. It satisfies the following relation:the first length < the second length < the third length…….< The 13th lengthMonitoring for...

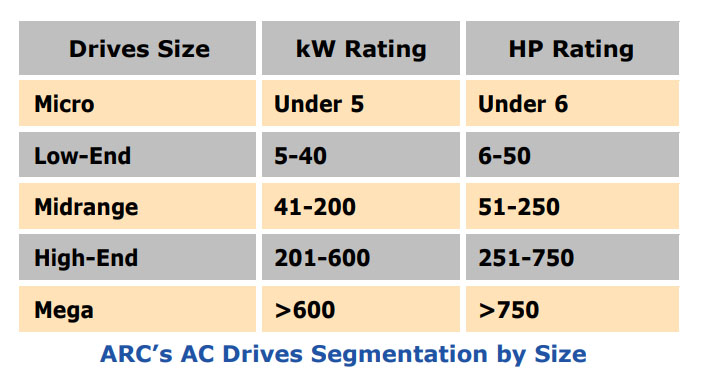

AC drives or Variable frequency drives control speed, torque, acceleration, deceleration, and rotation direction of AC motors. AC drives save energy by tailoring the power delivered to meet the actual load requirements. AC drives replace mechanical gearboxes, belts, hydraulic couplings, DC drives, servo drives, or eddy current drives in many situations. AC drives provide an accurate and wide range of smooth and step-less control of motor speed and torque in a highly efficient, low maintenance, compact size package. AC drives also provide versatile built-in functions, complex control, and networking capabilities and freedom from mechanical inertia and resonance. For AC drives, Pulse Width Modulated (PWM) technology is the primary industry standard. AC Drives or Variable Frequency Drives Classification by Size. ; ARC has segmented the AC drives market into five size ranges as defined by the drives’ output kilowatt and horsepower ratings. While ARC’s low power AC drives global market research study includes micro, low-end, and midrange drives, ARC’s high power AC drives global market research study includes the midrange, high-end, and mega drives markets. ARC has included midrange AC drives in both the low power and high power market studies. Many AC drives models have a very wide operating power range. For example, some suppliers offer a variation of the same model of AC drives that operates from low to high power ranges. Suppliers may offer a range of products that fall into multiple segmentations. Since such models can span different kilowatt segmentations, ARC has allocated the sales of these drives into their single most appropriate segmentation to avoid double counting. When AC drives are mounted on motors, this study only accounts for the drives portion, based on its appropriate AC drives type. Micro Drives Micro drives are the smallest units, controlling motors from a fraction of a kilowatt up to five kilowatts. Many micro drives models are basic and very similar to low-end drives models in technology and configurations. However, some suppliers offer micro drives that are simply lower power range versions of higher power range models, possessing many of the advanced features and functions of their higher-powered counterparts. Largely a commodity market, micro drives are used in various industrial and commercial machinery applications. Micro drives are usually sold through distributors or directly to large OEMs. Manufacturers of micro drives vary from small suppliers with drives as their sole products, to multinational conglomerates with a myriad of products. Most AC drives suppliers provide micro drives products. Low-End Drives Low-end drives control motors of 5 to 40 kilowatts. Many low-end drives models are basic and very similar to micro drives models in technology and configurations. Again, some suppliers offer low-end drives that are simply lower power range versions of higher power range models possessing many of the advanced features ...

◆ First step, must disconnected from the load. If the motor can be disconnected from the load, it can select rotation auto-tuning (P9.15=2), or it can select static auto-tuning only. ◆ If the inverter power does not match the motor power, select static auto-tuning. after the tuning, manually change the no load current P9.05 to about 40% of the motor rated current P9.04 ◆ Setting P0.01=5,recover parameter to factory setting ◆ Setting motor basic frequency P0.15 according to motor nameplate ◆ Setting motor rated voltage P0.12 according to motor nameplate ◆ Setting motor pole P9.01 according to motor nameplate ◆ Setting motor rated rotation P9.02 according to motor nameplate ◆ Setting motor rated power P9.03 according to motor nameplate ◆ Setting motor rated current P9.04 according to motor nameplate ◆ Setting P9.15=1 and pressure RUN key to perform static auto-tuning ◆ Setting P9.15=2 and pressure RUN key to perform static rotating-tuning, if perform rotating-tuning, should be careful because the motor will be run after pressure RUN key. ◆ After auto-tuning, the motor will stop auto. For Shenzhen V&T Technologies Co.,Ltd. Shenzhen V&T Technologies Co.,Ltd. is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a National Hi-tech enterprise and software enterprise, which has fully intellectual property rights and devotes to the R&D, manufacture, sales and technical service of variable speed drive (Variable frequency drive) , Servo Drives, Electric Vehicle Motor Controller(E-Drive), integrated elevator drives, Solar pump inverter ,etc.. V&T has won the “Technical Innovation” prize awarded by Inverter(AC Drive) Industry Association (IIA), the “The most competitive VFD brands” prize awarded by China Electrical Association, “Electric Vehicle Excellent Technology” Prize awarded by China Electro-Technical Society (CES). V&T has been ranked as one of the Top 10 Chinese AC Inverter (frequency drive) Enterprises. Shenzhen V&T Technologies Co.,Ltd. has completely grasped the key control technique and also possesses the capacity of industrialization design and manufacturing. It has developed lots of product series. The product voltage grade mainly contains 200V, 400V, 690V, 1140V, and the power grade varies from 0.4kW to 3000kW, which could meet various application demands from high, medium and low level market. Under the premise of meeting international standards , we further strengthened the product reliability and environment adaptability to suit harsh and extreme environments. Customized product and industrialized design can better meet medium and high level application demands. The products have been widely used in metallurgy, crane, oil, chemicals, machine tools, electric vehicles, metal processing, building materials, stone, wood processing, ceramics, plastics, air compressor, washing machine, water supply, air conditioning, municipal engineering, textile, printing, min...

When the Shenzhen V&T Technologies Co.,Ltd. inverter runs in vector control mode, it is highly dependent on accurate motor parameters, which is one of the important differences with V/F control mode.To ensure good driving performance and operating efficiency of the frequency inverter, the accurate parameters of the controlled motor can be obtained by three methods: static self-tuning (P9.15=1), rotary self-tuning (P9.15=2) and known parameters of the motor is input by hand . The first step: completely detach the motor from the load (it is recommended to detach the load) under the condition of complete power failure of the equipment, so that the motor can rotate freely without load. The second step: after power on, restore all parameters of the frequency inverter to the factory set value (this step is not required). The third step: "P0.12 maximum output voltage (motor rated voltage), P0.15 basic operating frequency (motor rated frequency), P9.01 motor pole number, P9.02 motor rated speed, P9.03 motor rated power and P9.04 motor rated current" are the basic parameters of the motor, which must be set correctly according to the actual parameters of the nameplate of the controlled motor. The fourth step: self-tuning on start parameters, please ensure that the motor is in a static state. P9.15=2 select the self-setting mode of rotation parameters and press the RUN key on the operation panel to display "-At-". At this time, the frequency inverter will drive the motor acceleration and deceleration operation, operators should pay attention to safety, tuning operation about 1 minute. After dynamic tuning, the frequency inverter will automatically calculate the key parameters of the motor (P9.05 ~ P9.14). Notes: 1.If there is a over-current and over-voltage fault in the self-setting process, the acceleration and deceleration time P0.08 and P0.09 can be appropriately extended. 2.If the frequency inverter and motor power do not match, please select static self-setting. After setting, it is necessary to manually change the no-load current P9.05 to about 40% of the rated current P9.04 in motor. 3.The value of magnetic saturation coefficient in P9.10 ~ P9.14 is automatically set in the self-setting time without user setting. 4.Static parameters are self-tuning. Press the "run" button to automatically measure motor parameters P9.06 ~ P9.08. 5.Key motor parameters that affect the operation control of the inverter are determined by performing self-tuning on parameters. These motor parameters will be automatically saved in the inverter after completing the self-tuning process until the next input parameter or self-tuning on parameter again. 6.If the motor can be off the load, it can choose to self-tuning on rotate, otherwise only static self-tuning. For Shenzhen V&T Technologies Co.,Ltd. Shenzhen V&T Technologies Co.,Ltd. is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a National Hi-tech ente...

When the Shenzhen V&T Technologies Co.,Ltd. frequency inverter is switched on, the action seems to be one step at a time, but have you ever thought about the information contained in this short moment? After the inverter has the condition of power on, close the power switch. During the normal power on in system, the status indicator light, unit indicator light and LED digital tube on the operation panel will suddenly light up.After the completion of self-inspection on frequency inverter. The sound of the contactor (relay) closing is heard.When operation panel displays 50.00, the Hz indicator is on and flashing continuously.When MON and FWD indicator are on, the whole process takes about 1 to 3 seconds. In the meantime, 15kW and below frequency drives (see user manual for details), fan operation after power on. In accordance with the above state, it means that the inverter is energized normally. The whole machine power content for you to introduce here. For Shenzhen V&T Technologies Co.,Ltd. Shenzhen V&T Technologies Co.,Ltd. is a listed company on shenzhen Stock Exchange Center,Stock code is 300484. V&T Company is certificated as a National Hi-tech enterprise and software enterprise, which has fully intellectual property rights and devotes to the R&D, manufacture, sales and technical service of Frequency Inverter(Variable frequency drive) , Servo Drives, Electric Vehicle Motor Controller(E-Drive), Solar pump inverter , Integrated elevator drive etc.. V&T has won the “Technical Innovation” prize awarded by Inverter(AC Drive) Industry Association (IIA), the “The most competitive VFD brands” prize awarded by China Electrical Association, “Electric Vehicle Excellent Technology” Prize awarded by China Electro-Technical Society (CES). V&T has been ranked as one of the Top 10 Chinese Inverter(frequency drive) Enterprises. Shenzhen V&T Technologies Co.,Ltd. has completely grasped the key control technique and also possesses the capacity of industrialization design and manufacturing. It has developed lots of product series. The product voltage grade mainly contains 200V, 400V, 690V, 1140V, and the power grade varies from 0.4kW to 3000kW, which could meet various application demands from high, medium and low level market. Under the premise of meeting international standards , we further strengthened the product reliability and environment adaptability to suit harsh and extreme environments. Customized product and industrialized design can better meet medium and high level application demands. The products have been widely used in metallurgy, crane, oil, chemicals, machine tools, electric vehicles, metal processing, building materials, stone, wood processing, ceramics, plastics, air compressor, washing machine, water supply, air conditioning, municipal engineering, textile, printing, mining and other industries.

When Nikola Tesla developed and patented the AC induction motor in 1924 (as well as the syncronous and split phasemotors) it had the endearing characteristic that it can be run by direct connection to a three phase power source. The motor speed is directly proportional to the applied frequency and is determined by the formula n = 120f/p where n is the synchronous speed of the motor in rpm, f is the frequency of power applied and p is the number of poles on the rotor. Therefore a 2 pole induction motor running at 60 Hz will run at 3600 rpm synchronous speed less the slip required to produce the induction effect at full load. This slip is variable depending on the motor design but for the “standard” NEMA design B motor it is 3 to 5 % making the typical 2 pole motor run at 3500 rpm at full load at 60 Hz. Soon after the AC motor was developed, the idea of varying the speed was considered and the only practical way of doing this at the time was to provide the motor with a variable frequency obtained by using a DC motor turning an AC alternator which allowed a variable frequency. This was done on a wide range of applications in the 50s, 60s, and 70s. Since the much simpler Ward-Leonard system existed for DC motors, however the major use for such lines was in precision controlled multimotor lines where synchronous AC motors were used for each section and when the master alternator frequency was varied, all the motors would follow together with synchronous accuracy. Such systems were still being installed on new machines as late as the mid 80s when static variable frequency controls became widely used. Static AC variable speed drives that were readily available were of the six step, variable voltage design. Later, when Phillips/Signetics came out with a sine coded PWM chip set, sine coded PWM drives became the norm and six step variable frequency faded into non-use except for unusual applications where the slightly lower loss at full speed, full load was an advantage. An induction or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is induced by electromagnetic induction from the magnetic field of the stator winding. An induction motor therefore does not require mechanical commutation, separate-excitation or self-excitation for all or part of the energy transferred from stator to rotor, as in universal, DC and large synchronous motors. An induction motor’s rotor can be either wound type or squirrel-cage type. Three-phase squirrel-cage induction motors are widely used in industrial drives because they are rugged, reliable and economical. Single-phase induction motors are used extensively for smaller loads, such as household appliances like fans. Although traditionally used in fixed-speed service, induction motors are increasingly being used with variable-frequency drives (VFDs) in variable-speed service. VFDs offer especially important energy savings opportunities for existing and prospective i...

When Tesla first introduced the 3-phase alternating current (AC) induction motor in 1888, he knew that his invention was more efficient and reliable than Edison's direct current (DC) motor. However, AC motor speed control requires either varying the magnetic flux or changing the number of poles on the motor. Even decades after the induction motor gained widespread use, changing the frequency for speed control remained an extremely difficult task — and the physical construction of the motor prevented manufacturers from creating motors with more than two speeds. As a result, DC motors were necessary where accurate speed control and significant power output were required. In contrast to AC motor speed control requirements, DC motor speed control was achieved by inserting a rheostat into the low-power DC field circuit, which was feasible with available technology. These simple motor controls varied the speed and torque, and were the most economical way to do so for a number of decades. By the 1980s, AC motor drive technology became reliable and inexpensive enough to compete with traditional DC motor control. These variable frequency drives (VFDs) accurately control the speed of standard AC induction or synchronous motors. With VFDs, speed control with full torque is achieved from 0 rpm through the maximum rated speed and, if required, above the rated speed at reduced torque. VFDs manipulate the frequency of their output by rectifying an incoming AC current into DC, and then using voltage pulse-width modulation to recreate an AC current and voltage output waveform. However, this frequency conversion process causes 2% to 3% loss as heat in the VFD — caloric energy that must be dissipated. The process also yields over-voltage spikes and harmonic current distortions. Variable-frequency types There are three common types of VFDs. Current source inversion (CSI) has been successfully used in signal processing and industrial power applications. CSI VFDs are the only type that has regenerative power capability. In other words, they can absorb power flow back from the motor into the power supply. CSI VFDs give a very clean current waveform but require large, expensive inductors in their construction and cause cogging (pulsating movement during rotation) below 6 Hz. Voltage source inversion (VSI) drives have poor power factor, can cause motor cogging below 6 Hz, and are non-regenerative. Consequently, CSI and VSI drives have not been widely used. Pulse-width modulation (PWM) VFDs are most commonly used in industry because of excellent input power factor due to fixed DC bus voltage, no motor cogging, higher efficiencies, and lower cost. A PWM VFD uses a series of voltage pulses of different lengths to simulate a sinusoidal wave (Fig. 1 on page 8). Ideally, the pulses are timed so that the time average integral of the drive yields a perfect sinusoid. The current method of choice to produce this waveform runs a triangle wave and sine wave through a comparator, and...

Categories

Copyright © 2024 Shenzhen V&T Technologies Co.,Ltd.. All Rights Reserved. Power by

IPv6 network supported